Customer Background

An international mining group in the copper mine project in South America has long faced the problem of tailings dewatering. The high humidity and high salt content in the mining area led to the fouling and blockage of the filter liquid pipelines of traditional open-flow filter presses, and the manual operation efficiency was very low. The moisture content of the tailings could never be reduced below 40%, which seriously affected the transportation efficiency and environmental compliance.

Pain point analysis

Filter liquid discharge issue: Open flow design causes filter liquid to splash, corroding the equipment frame

High dependence on humans: Two operators are required to be on duty per shift, resulting in high labor costs.

Insufficient dehydration efficiency: The single-cycle processing time is as long as 90 minutes, and the production capacity bottleneck is obvious.

Solution

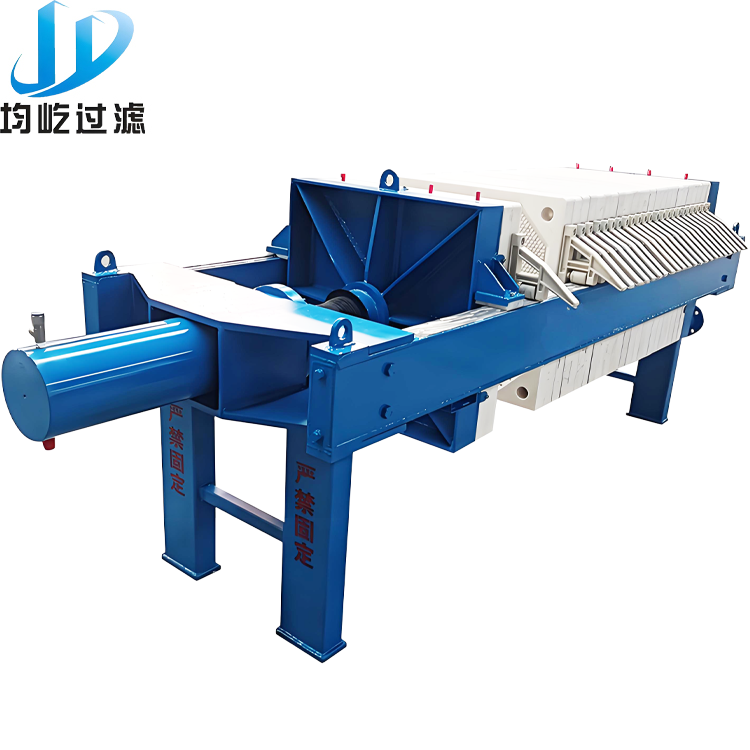

We customized a 630 submerged-flow automatic hydraulic pressure filter for it. The core configuration includes:

✔ Fully enclosed submerged-flow system: Integrated liquid collection pipeline at the bottom, completely solving the problem of splashing and corrosion

✔ Automatic hydraulic system: Full automation of the pressing/holding/emptying process, reducing the number of operators to 0.5 per shift

✔ Intelligent PLC control: Automatically adjusts the pressure curve according to the concentration of the ore slurry, compressing the single cycle time to 55 minutes

Implementation effect

Dewatering efficiency: The moisture content of tailings decreased from 42% to 33%, meeting the international transportation standards.

Capacity increase: The daily processing capacity has been raised from 800 tons to 1500 tons (with the same number of equipment)

Cost savings:

Labor costs have decreased by 60%

The maintenance interval has been extended from 3 months to 18 months.

The service life of the filter cloth is extended by 40% (the backflow design reduces the impact of hard objects)

Environmental benefits: Achieve “zero liquid spillage” within the factory area

“The concealed design of this equipment is truly tailor-made for our mining area! Not only has it saved us the time spent cleaning up spilled filtrate every day, but the automatic hydraulic system has also doubled our production capacity.” —— Director of Operations of the Customer’s Mineral Processing Plant

Post time: Aug-08-2025