Industry: Industrial Park Wastewater Treatment and Reuse

Challenges: Inconsistent pre-treatment results led to frequent blockages of the subsequent membrane system, resulting in high maintenance costs.

I. Customer Background and Core Pain Points

Our client is the operation management entity of a large industrial park. To achieve its sustainable development goals, this park invested in an advanced wastewater recycling system, aiming to utilize the treated industrial wastewater for park greening, road washing, and cooling tower water replenishment. However, since its operation, the core membrane processing unit (RO reverse osmosis) of this system has repeatedly experienced irreversible blockages and contamination, resulting in a significant drop in production volume. Frequent chemical cleaning and even replacement of membrane elements are required, causing extremely high maintenance costs.

After investigation, the root cause of the problem lies in the unstable filtering effect during the pre-treatment stage. The wastewater from different enterprises in the park has complex components and fluctuating suspended solids (SS) concentrations. The original sand filtration system is unable to effectively intercept fine particles and colloidal substances, and these pollutants directly enter the sophisticated membrane system, ultimately leading to serious problems. The customer urgently needs an efficient and stable pre-treatment filtration solution to provide a solid and reliable “umbrella” for the expensive membrane system.

II. Our Solution

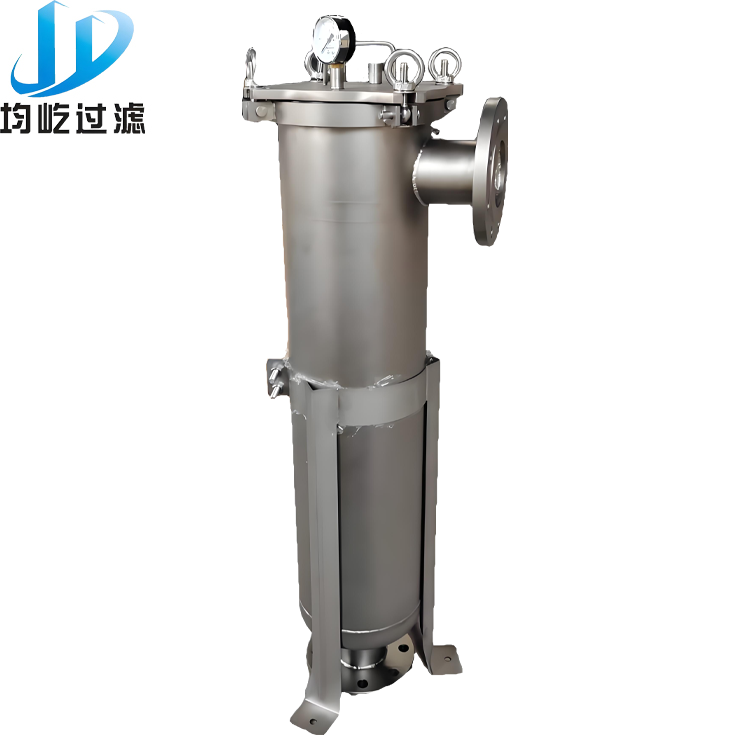

Given the characteristic of significant fluctuations in the wastewater quality of the park and the requirement for continuous operation, we have proposed an upgraded solution featuring a bag filtration system as the core pre-treatment unit.

Precise accuracy matching: Through water quality analysis, we have selected the most suitable filtration accuracy for our customers. The filter bags with this accuracy can efficiently remove the vast majority of suspended solids and colloids in the raw water, significantly reducing the pollution load on the downstream membrane, while also avoiding the rapid clogging of the filter bags due to excessive precision.

Enhanced anti-clogging capability: For the possible presence of oils and viscous substances in wastewater, we recommend using filter bags that have undergone special surface treatment. These filter bags are less prone to clogging, thereby extending the filtration cycle.

Minimalist operation and maintenance management: The quick-opening design and standardized filter bags make the replacement process extremely simple. Ordinary staff can handle it after a brief training, significantly reducing the reliance on professional maintenance personnel.

III. Significant Value Delivered to Customers

After the implementation of this pre-treatment filtration system, the overall operation status of the wastewater reuse system in the park has been fundamentally improved:

The membrane system is fully protected: The chemical cleaning frequency of the RO membrane has been extended from the original once a month to once every quarter or more. The expected service life of the membrane elements has been significantly prolonged, directly saving customers a large amount of chemical costs and equipment replacement expenses.

The system’s operational stability has been significantly enhanced: The treated effluent quality is stable and controllable, resolving the “major concern” of the subsequent membrane system operation. The reliability and availability of the entire reuse system have reached the design goals.

Life cycle cost reduction: The investment in bag filtration systems is much lower than the cost of replacing membrane elements, and the daily maintenance costs are also very low. Customers have calculated that the investment return period (ROI) is very short, achieving significant economic benefits.

The water conservation goal was successfully achieved: The stable system operation ensured the wastewater reuse rate, and the park saved a large amount of fresh water resources each year, thus fully meeting the environmental protection and water conservation goals.

Customer review:

“The minimal investment in the pre-treatment stage solved the biggest operational problem for our system. This bag-type filtration system is like giving our membrane system a sturdy ‘protective suit’. Its stability and ease of maintenance left a deep impression on us, allowing us to focus on the core operation management of the park.”

Post time: Sep-24-2025