In the palm oil processing industry chain, the filtration stage directly determines the quality of crude oil and the subsequent refining cost, making it a key node for enhancing product competitiveness. With the global palm oil industry’s upgrading of quality standards and tightening of environmental protection requirements, leaf filters have stood out among numerous equipment due to their exclusive design tailored to the characteristics of palm oil, becoming the core equipment for processing enterprises to improve quality and efficiency.

The problems to be solved by customers: Palm oil has high viscosity and complex impurities (including fruit pulp residue, colloids, and fine particles), and the processing process has high requirements for temperature stability. Traditional equipment has become difficult to meet modern production needs. Industry data shows that traditional processes require frequent shutdowns for cleaning, with annual filter cloth wear and tear costs, and the high-pollution wastewater generated also requires additional treatment costs. These pain points directly restrict the profit margins of enterprises.

The reason why leaf filters have become the preferred solution for palm oil filtration lies in their in-depth optimization for the oil processing scenario.

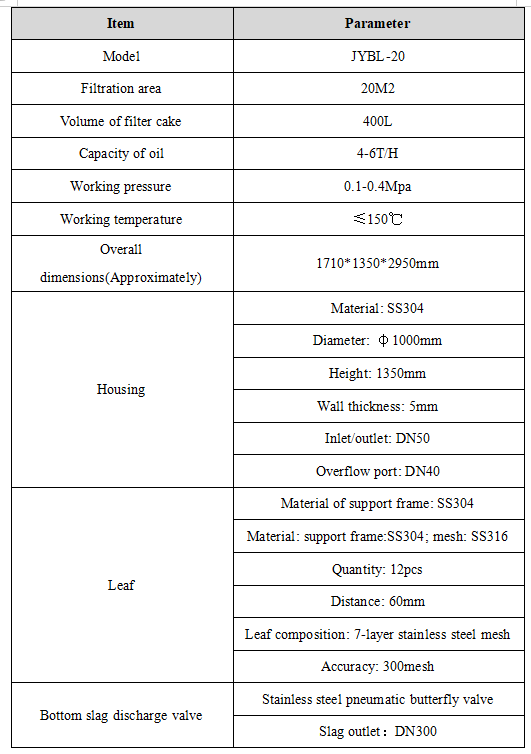

Leaf filters use stainless steel composite woven filter screens and achieve micron-level retention through a multi-layer gradient filtration structure. This high-precision filtration not only reduces the consumption of additives in subsequent refining steps but also avoids the oxidation and deterioration of oil caused by impurities, extending the product’s shelf life.

No consumables design, significantly reducing operating costs. Leaf filters completely abandon filter cloths, filter papers, and other consumables, requiring only a small amount of filtration aids. The core filter screen, with its resistance to the acidic corrosion of palm oil, can last for 3 to 5 years. At the same time, the fully enclosed operation of the equipment avoids the oxidation loss caused by the contact of oil with air, greatly improving the material recovery rate and reducing the emission of volatile organic compounds.

Automated slag discharge, enhancing production continuity. Leaf filters achieve automated slag discharge control through the linkage design of hydraulic drive and vibration slag discharge systems – the slag discharge time is significantly shortened, and the effective production time is increased. The fully enclosed operation mode of leaf filters can prevent oxidation loss caused by the contact of oil with air, greatly improving the material recovery rate and reducing the emission of volatile organic compounds.

The palm oil industry is facing dual challenges of quality upgrading and cost control. Leaf filters, with their high efficiency, energy conservation, and low maintenance characteristics, have become the preferred equipment for technical transformation in palm oil processing enterprises. With the popularization of automated filtration technology, it will further promote the process of quality improvement and efficiency enhancement in the global palm oil industry.

Post time: Dec-18-2025