I. Customer background and pain points

This food processing plant specializes in the production of high-end traditional fermented seasonings. The factory is proud of its ancient brewing techniques and pure natural formulas, and its products enjoy a high reputation in the market. However, at the final crucial step of liquid clarification in the production process, they encountered huge challenges.

Limitations of traditional methods: The factory has long relied on natural sedimentation and simple bag filtration. This method is extremely time-consuming (often requiring several days or even weeks), seriously occupying storage tank space, slowing down the entire production cycle, and being unable to cope with sudden increases in orders.

Inconsistent quality: The natural sediment cannot completely remove extremely fine yeast cells, protein colloids and precipitates, resulting in the product having a rich taste but insufficient clarity. Occasionally, sediment appears at the bottom of the bottle, which affects the image of high-end products and the consumer experience.

Health and cost risks: The lengthy sedimentation process increases the risk of product contamination by microorganisms. Additionally, the frequent cleaning of the filter bags and manual operations also bring about relatively high hidden labor costs.

II. Solution

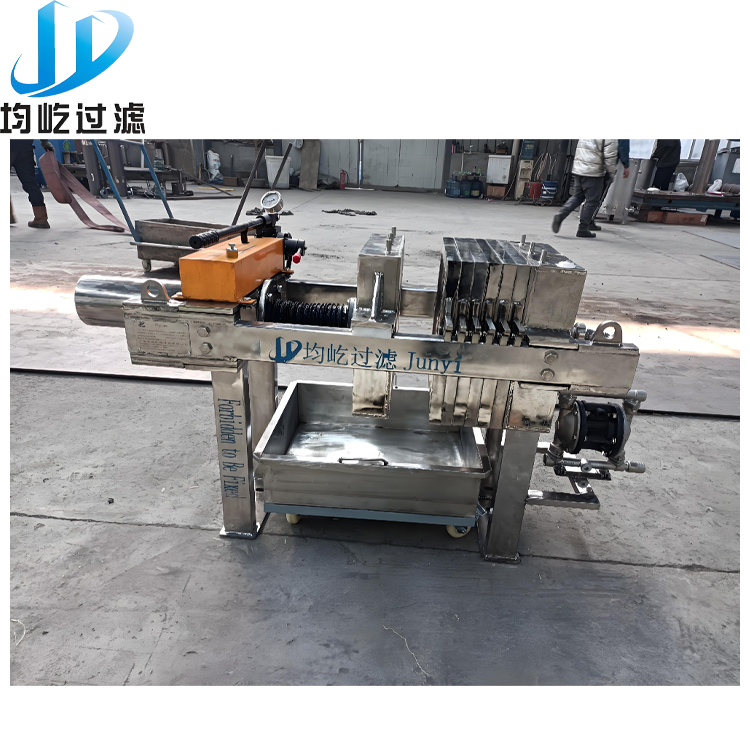

To address the aforementioned problems, this factory introduced a manual hydraulic stainless steel box-type filter press.

Material selection: We choose models made of fully food-grade stainless steel. This ensures that the entire filtration process complies with strict food hygiene and safety standards, and does not introduce odors or heavy metal contamination. It perfectly aligns with the positioning of our high-end products.

Operation method: The manual hydraulic pressing method is an ideal solution for old workshops without power supply. It does not require complex circuit modifications. The operation is simple, and workers can get started with it after a brief training. The stable high pressure provided ensures zero leakage during the filtration process.

Precise filtration: According to the characteristics of its products, specific precision food-grade filter cloths have been selected to ensure that all insoluble particles and colloidal substances can be completely and once again retained.

III. Achieved Value and Results

Since the equipment was put into use, the quality of the final products and production efficiency of this factory have achieved a qualitative leap:

Product quality has significantly improved:

Extremely clear: The filtered finished vinegar liquid exhibits an astonishingly transparent luster, without any suspended matter or sediment. Its appearance quality immediately surpasses that of most competitors.

Authentic flavor: Rapid filtration reduces the product’s exposure time in the air, better preserving its original flavor components, resulting in a more pure and pleasant taste.

Extended shelf life: Completely removed microbial carriers (yeast, etc.), enhancing the biological stability of the product and extending the product’s shelf life.

Revolutionary change in production efficiency:

The time has changed from “days” to “hours”: The previously required several-day sedimentation process has been shortened to an active filtration operation taking less than one hour. The production batch turnover rate has significantly increased, releasing valuable storage tank resources.

Save a significant amount of manpower: Say goodbye to the cumbersome and inefficient manual dumping and cleaning tasks. Now, only one worker is needed to easily complete the unloading and filter cloth cleaning, resulting in a substantial reduction in labor costs.

Significant economic benefits:

Although it is an investment in a one-time equipment, the savings in labor costs, time costs, as well as the brand premium and customer satisfaction resulting from the improvement of product quality, make the investment return period very short.

Conclusion:

For this food factory that adheres to tradition while also yearning for modernization, this manual hydraulic filter press is not merely a cold machine; rather, it represents the perfect fusion of its traditional craftsmanship and modern efficiency. It successfully presents the essence of “ancient brewing” in the clearest, most stable, and most efficient manner to the market, completely resolving the development bottlenecks that have plagued it for years.

Post time: Aug-20-2025