Project Background

A century-old brewery in Germany is facing the problem of low filtration efficiency in the initial fermentation:

Processing capacity requirement: 4500L/h (including 800kg of solid impurities)

Process temperature: > 80℃

Pain points of traditional equipment: efficiency is less than 30%, and manual cleaning takes 25%

Solution

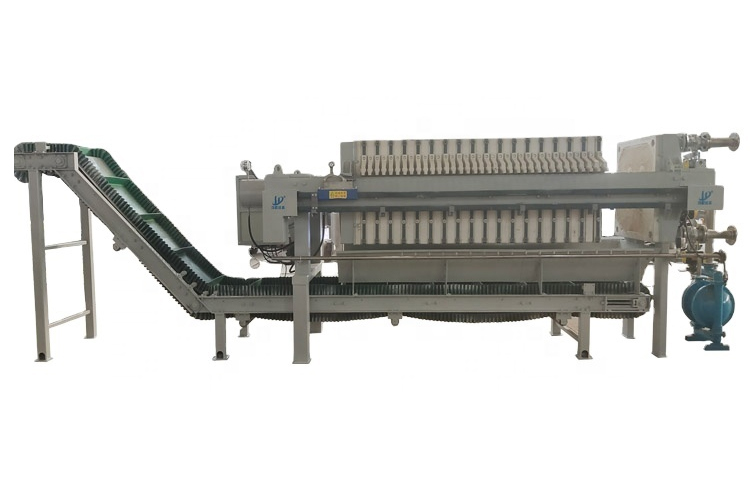

Adopt the XAY100/1000-30 filter press system:

High-temperature resistant PP filter plate (85℃) in combination with carbon steel structure

2. 100 square meters filtration area + automatic unloading design

3. Intelligent membrane plate combination + conveyor belt system

Implementation effect

Processing capacity: Stably reaching 4500L/h

Efficiency improvement: The filtration efficiency has increased by 30%

Operation optimization: Reduce labor by 60% and lower energy consumption by 18%

Customer review: “Automatic unloading reduces operation time by 40%.”

Industry value

This case proves that professional filter press equipment can effectively solve the filtration problem of high solid content in the brewing industry, providing a practical sample for the modernization of traditional processes. Through technological innovation, this diaphragm filter press has achieved a dual improvement in efficiency and quality.

Post time: Apr-25-2025