Customer Background

Industry: Mining and Metal Processing

Challenges:

The mining wastewater contains sludge with high concentrations of heavy metals. The traditional pressure filtration equipment has low efficiency and insufficient processing capacity, which affects the production schedule.

The moisture content of the filter cake is as high as 35%, which fails to meet the environmental emission standards and is under regulatory pressure.

The cost of manual operation is high, equipment maintenance is frequent, and downtime is long.

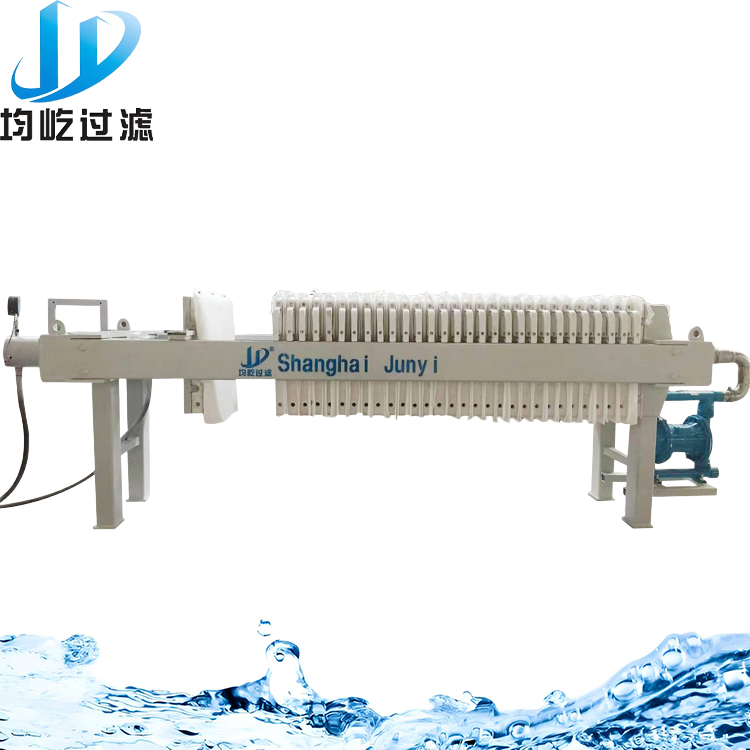

Solution: Fully Automatic Hydraulic Box-type Filter Press

After thorough research and evaluation, we finally chose our company’s fully automatic hydraulic box-type filter press.

This equipment boasts the following core advantages:

✔ Efficient Dewatering – The moisture content of the filter cake is reduced to below 17%, far exceeding industry standards, and easily meeting environmental protection requirements.

✔ Intelligent Automation – The PLC control system enables one-click operation, reducing reliance on manual labor and ensuring more stable operation.

✔ Exceptional Durability – Special filter plates and anti-corrosive hydraulic system, capable of withstanding high acid and alkali environments, increasing the equipment lifespan by 50%.

✔ Energy-saving and Environmentally Friendly – Integrated water recycling system, reducing water consumption by 30% and lowering operating costs.

Implementation effect

Processing capacity increased by 140%: From the original 50 tons per day to 120 tons per day, significantly enhancing production efficiency.

The moisture content of the filter cake has been reduced to 17%: This fully complies with environmental protection standards and avoids the risk of fines.

Labor cost saved by 75%: From a four-person shift to only one person for monitoring, significantly reducing the manpower input.

Maintenance frequency reduced by 80%: Equipment failure rate significantly decreased, ensuring continuous and stable production.

Customer Review

“We had been struggling with low efficiency and high costs in sludge treatment before. Since we adopted the junyi fully automatic hydraulic box-type filter press, not only has the treatment capacity doubled, but the moisture content of the filter cake has also significantly decreased, helping us successfully pass the environmental protection inspection. Moreover, the automated operation reduces the need for manual intervention, resulting in substantial annual operational cost savings. This is a very successful equipment upgrade!” — Head of Environmental Engineering Department

Post time: Jul-23-2025