I. Project Background: Core requirements of high-temperature sodium silicate filtration

Sodium silicate is an important inorganic chemical raw material widely used in industries such as detergents, construction, and textiles. The client in this cooperation is a well-known chemical enterprise in Sri Lanka, mainly engaged in the production and sales of sodium silicate series products. With the expansion of market demand, the client’s original filtration equipment has been unable to meet production requirements, facing many technical challenges.

The core demand of the client is clear: to achieve stable filtration processing of 8 tons of sodium silicate per day, with the filtration temperature maintained at 80℃. Sodium silicate has the characteristics of high viscosity and easy crystallization at high temperatures, and the original slurry contains insoluble silicate impurities such as iron, aluminum, calcium, and magnesium. If the filtration accuracy is insufficient, it will seriously affect the purity of the product, thereby affecting the use of downstream customers. At the same time, the client requires that the filtration system operates efficiently and stably, can reduce the cost of manual maintenance, and complies with local environmental protection and production safety standards.

II. Solution: Customized pressure filter + screw pump filtration system

In response to the client’s high-temperature and high-viscosity material filtration requirements, combined with the material characteristics of sodium silicate, we have customized an integrated filtration solution with an efficient pressure filter as the core and a dedicated screw pump as a supplement. From equipment selection, process optimization to system integration, we comprehensively ensure the filtration effect and production efficiency.

1. Core equipment selection: Pressure filter suitable for high-temperature conditions

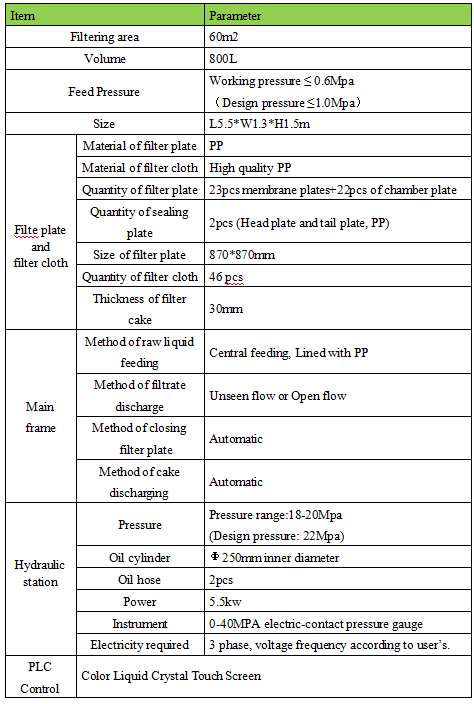

Considering the 80℃ high-temperature condition, conventional polypropylene filter plates are prone to deformation. We selected a stainless steel 316L material pressure filter. This material has strong corrosion resistance and excellent high-temperature performance, which can effectively avoid filter plate deformation and leakage problems under high-temperature conditions. At the same time, based on the daily 8-ton processing volume, the filtration area was accurately calculated, and the corresponding filter chamber volume and filter cloth specifications were configured – the filter cloth uses high-temperature-resistant polypropylene material, with a pore size slightly smaller than the D90 value of the target impurities, which can efficiently capture impurities while ensuring filtration flow rate and avoiding “runaway” phenomenon.

To further improve the filtration efficiency, the pressure filter system incorporates pressure difference control technology. When the internal and external pressure difference of the filtration device is greater than 0.2MPa, the system automatically adjusts the pressure at the filter liquid outlet to maintain the pressure difference within a safe range, effectively extending the filtration cycle and increasing filtration volume and speed. In addition, the equipment is equipped with a semi-automatic control system, which can achieve automatic pressing, discharging, and significantly reduce the manual operation intensity.

2. Conveyor system matching: Dedicated screw pump ensures stable feed

The sodium silicate slurry has high viscosity and contains solid impurities. Ordinary conveying pumps are prone to blockage and wear. We provided the client with a wear-resistant screw pump, which has stable flow and small pressure pulsation, and can meet the conveying requirements of high-viscosity and particle-containing materials. The rotational speed of the screw pump can be adjusted by frequency conversion to precisely match the feeding speed of the pressure filter, avoiding filter plate blockage due to excessive feeding speed or affecting production efficiency due to insufficient feeding speed. At the same time, the pump body and the conveying pipeline are equipped with wear-resistant ceramic liners to enhance wear resistance and extend the equipment service life.

Post time: Dec-25-2025