Recently, Shanghai Junyi Filter Equipment Co.,Ltd, with stable product quality and efficient customized service, successfully won the second cooperation order of old customers in Suzhou (contract No. : JY20251203GL, order No. 1604), customized production of a set of special filter basket. In this cooperation, the customer clearly requires “accurate production in full accordance with the drawing size“. Junyi successfully delivers it with strict precision control and standardized production process, which once again confirms the company’s hard strength in the field of customized filtration accessories, and also shows the high recognition of Junyi’s products and services by old customers.

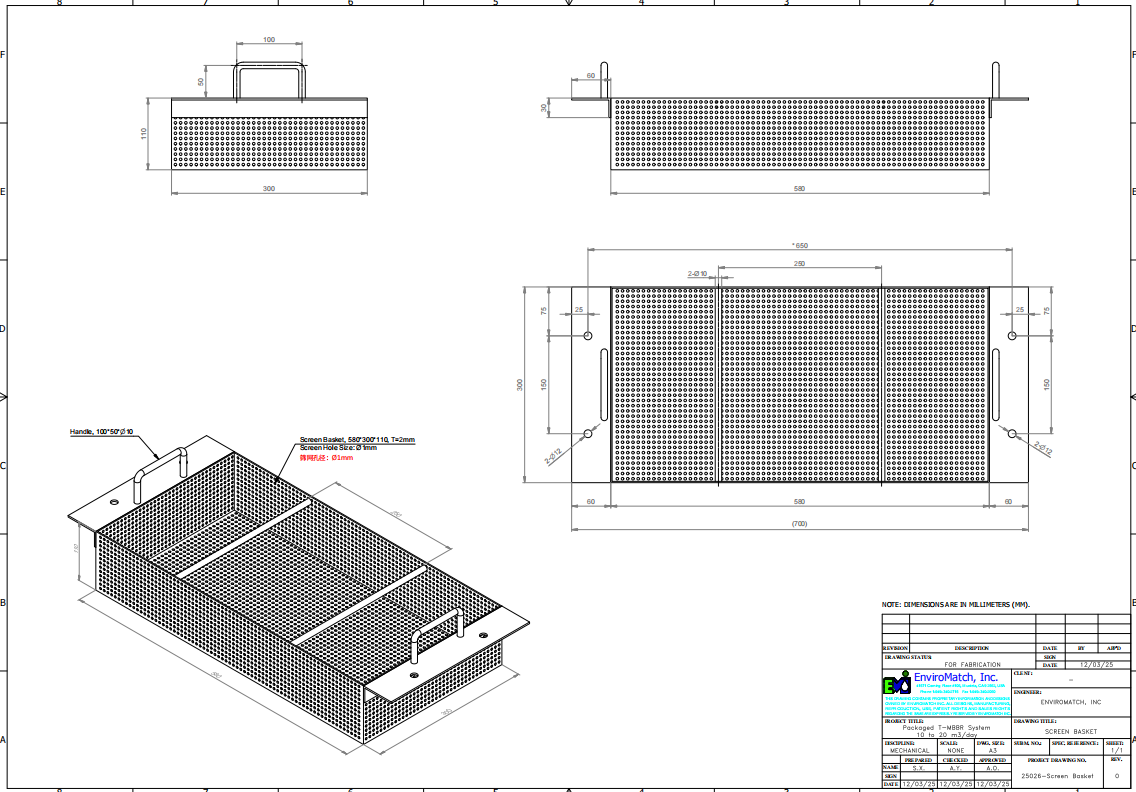

As an old customer of the second cooperation, based on the use scenario of JYBF25-304 basket filter purchased previously, the Suzhou customer directly provided detailed design drawings of the filter basket, clearly marked the key parameters such as material, accuracy and thickness, and the core appeal focused on “zero deviation in size and no error in adaptation“. After receiving the demand, the Jun Yi technical team immediately docking customers, one by one review of the drawing details: confirm that the filter basket needs to be suitable for the original basket filter barrel structure, the key size needs to accurately fit the equipment cavity, and meet the dual needs of impurity interception and circulation efficiency in industrial fluid filtration.

According to the customer’s core requirements of “accurate production according to the drawing”, the technical team has developed a special production plan: taking the drawing as the only implementation standard, the material, accuracy, thickness and other parameters of the filter basket are disassembled into the key points of production – the 304 stainless steel material is clearly used (the material adaptability of the previous equipment is continued to ensure corrosion resistance, easy cleaning, and suitable for a variety of industrial media); Strictly control the filter basket accuracy of 1mm, to ensure efficient interception of the corresponding particle size of impurities; The thickness is set to 2mm, taking into account both structural strength and filtration flux. At the same time, the technical team synchronizes the drawing details with the production department in advance, marks the key dimension tolerance range, and lays a solid foundation for precise production. After checking the drawings, the first time feedback customer confirmation, with professional and efficient response speed to win customer recognition.

Seiko: whole process control, build a strong quality line of defense

Based on the confirmed design drawings, we implement the whole process of fine control in the production process of the filter basket to ensure that every detail is highly consistent with the drawing standards:

• Strict material control: high-quality 304 stainless steel raw materials are selected, and the material composition is confirmed by spectral detection before entering the field to ensure that the corrosion resistance and oxidation resistance are up to the standard, and the customer’s original basket filter barrel material is perfectly matched to avoid compatibility problems in long-term use;

• Precision control: CNC stamping, laser cutting and other high-precision processing equipment are used to accurately process the key dimensions of the filter basket, such as aperture, diameter and height. After each process, special personnel are arranged to measure against the drawings one by one to ensure that the size deviation is controlled within ±0.1mm, which fully meets the strict requirements of “production according to the drawing”.

• Structural optimization: Combined with the feedback of the previous equipment, the edge smoothness and interface fit of the filter basket are optimized in detail on the basis of fully following the drawing size, so as to ensure seamless docking with the basket filter cavity during installation, convenient disassembly and assembly, and reduce the daily maintenance cost of customers.

Service escort: transparent throughout, efficient delivery worry-free

In the process of order promotion, the salesman continues the “customer-centric” service concept of Jun Yi, and maintains close communication with customers throughout the process: timely synchronization of raw material procurement, production progress, quality inspection results and other key node information, so that customers can grasp the order dynamics in real time; In view of the details of the drawings proposed by customers, the first time linkage technical team to provide professional answers to eliminate customer concerns.

After the production is completed, the customized filter basket is packed in solid carton according to customer requirements, and arranged to be shipped through logistics together with the 1598# order (the previous basket filter order), which not only ensures the safety of product transportation, but also saves logistics costs for customers. At the same time, the company promises that the set of filter basket enjoys the standard quality assurance policy consistent with the whole machine. The professional after-sales team will respond to the customer’s installation guidance, use consultation and other needs in a timely manner, and remove the customer’s concerns in an all-round way.

As a professional manufacturer in the field of deep cultivation filtration equipment and accessories, Shanghai Junyi has always taken “accurate adaptation, reliable quality” as the core, and has won the long-term trust of many customers with the service advantages of “customized according to the drawing, controllable precision and fast response”. The second purchase of Suzhou customers is not only the recognition of Junyi product quality, but also the affirmation of the company’s customized service ability. In the future, Jun Yi will continue to polish the production process, optimize the service process, and provide more accurate and more efficient customized filtration solutions according to the drawing needs and working conditions of different customers, and continue to create value for customers.

Post time: Dec-10-2025