Recently, Shanghai Junyi Filter Equipment Co.,Ltd, with mature customization service capabilities, successfully completed Suzhou customer basket filter customization order (contract No. : JY20251124GL), three JYBF25-304 basket filters were delivered to customers. In this cooperation, the customer only provides a simple reference sketch, and the design department responds quickly and accurately. After completing the full set of complete design drawings and being confirmed by the customer, the production is promoted efficiently, which perfectly matches the actual working conditions of the customer, highlighting the company’s technical strength and service advantages in the field of customized filtration equipment.

Sketch to design: Accurately deconstruct requirements, custom design landing

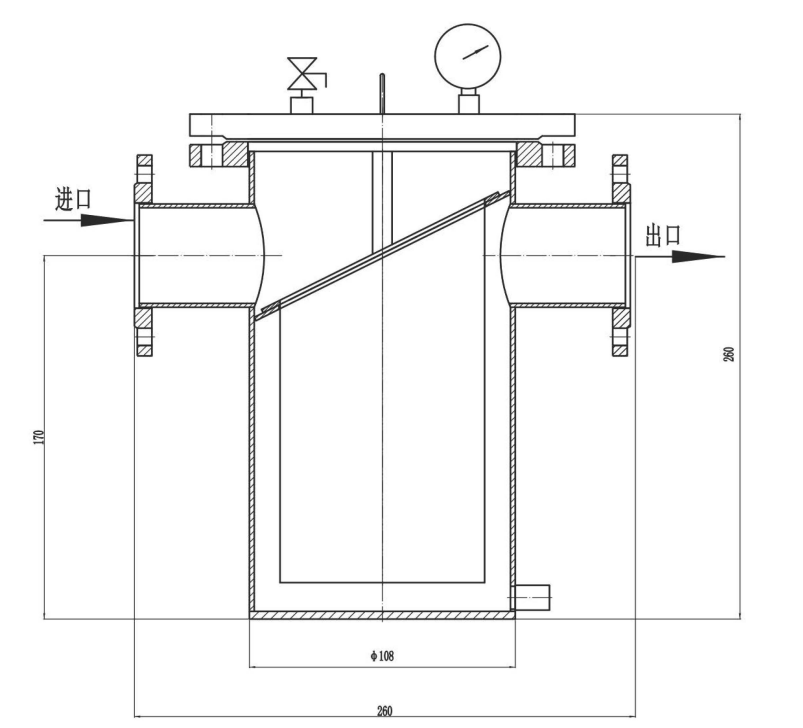

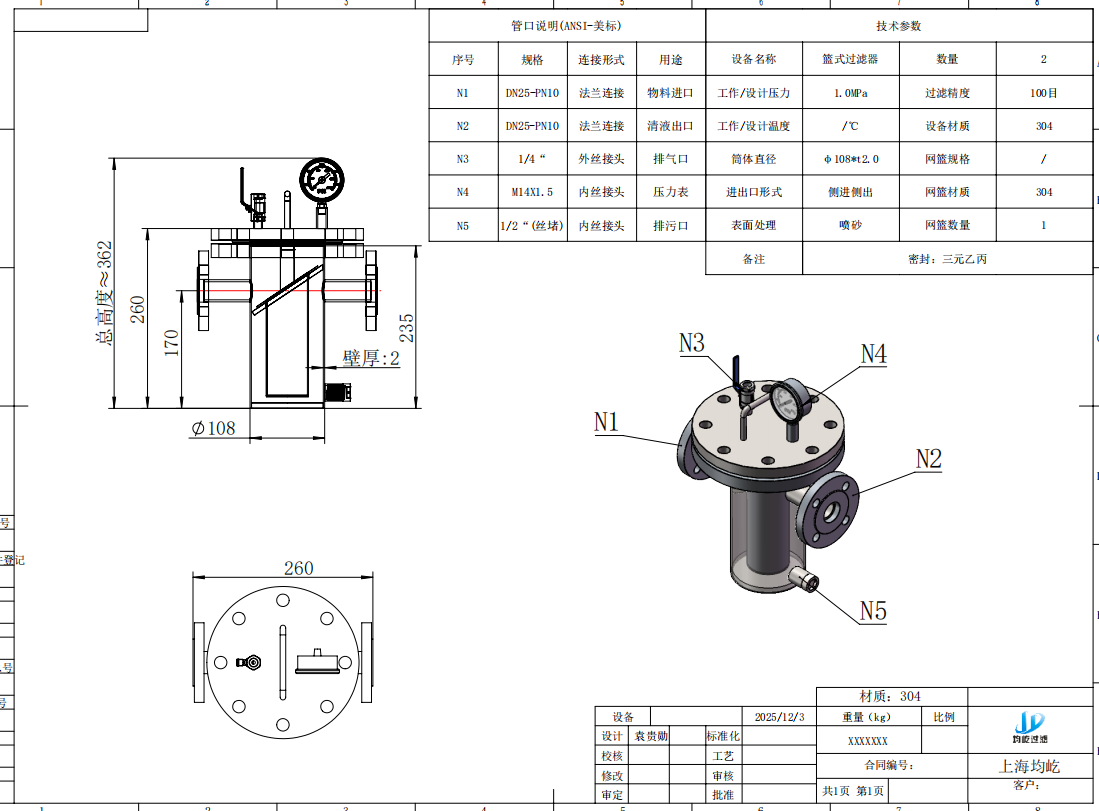

The core highlight of this cooperation is the efficient transformation from simple sketches to professional design drawings. Based on their own production scene needs, the customer provided a simple reference sketch including import and export orientation and core size annotation, and clarified the basic working condition requirements for equipment adaptation. After receiving the demand, the design department of the first time to organize the technical team docking, in-depth disassembly of the key information in the sketch: combined with the customer’s potential fluid filtration needs, supplement the details of the equipment structure, sealing scheme, pressure adaptation parameters and other professional design content, and finally form a complete standardized design.

In the design process, the technical team fully considered the practicability and stability of the industrial scene: in view of the media impurity interception requirements that customers may face, the filter basket accuracy of 100 mesh (corresponding to 150 microns) is specified to ensure efficient interception of impurities; Adapt to the pipe installation specification, set the import and export specifications to 1-inch American standard flange, improve the compatibility of the equipment with the customer’s existing system; At the same time, the structure layout of the equipment is optimized, and 1/2 inch sewage outlet and 1/4 inch exhaust outlet are added to solve the problem of residue discharge and air retention in the filtration process, and ensure the smooth filtration process. After the completion of the design drawing, timely synchronous customer confirmation, in view of the details of the customer questions for professional answers, and finally reach a consensus, lay a solid foundation for subsequent production.

Core configuration upgrade: focus on working condition adaptation, build a strong quality defense line

Based on the confirmed design drawing, the customized JYBF25-304 basket filter is optimized around the actual needs of customers in terms of material, structure and performance, and the core configuration is both practical and reliable:

- Material selection: the equipment cylinder and filter basket are made of 304 stainless steel. The surface of the cylinder is sandblasted, which not only has excellent corrosion resistance, is suitable for a variety of industrial fluid media, and is easy to clean, hygienic, and reduces daily maintenance costs.

- Sealing and pressure guarantee: the EPDM sealing ring is adopted, which has excellent sealing performance and is suitable for stable operation under normal temperature conditions. At the same time, the ordinary pressure gauge is equipped to monitor the filtration pressure in real time. The designed pressure of the equipment is up to 1.0MPa, which meets the pressure demand of conventional industrial filtration.

- Structural optimization: the diameter of the cylinder is 108mm, compact structure, small footprint, suitable for the spatial layout of the customer’s production site; The filter basket and cylinder are precisely matched, easy to disassemble and install, easy to clean and replace the filter basket in the later stage, and improve production efficiency.

Production and service: whole process control, efficient delivery without worry

In the production process, we strictly follow the requirements of the design drawings and implement the quality control of the whole process: from the procurement and inspection of raw materials, to the barrel processing, the filter basket molding, and the assembly of accessories, each process has passed the professional quality inspection to ensure that the equipment parameters are consistent with the design standards. According to the transportation requirements of the equipment, the firm carton packaging is adopted to effectively avoid the collision damage in the transportation process and ensure that the equipment arrives at the customer site in good condition.

According to the order agreement, 2 sets of customized basket filters have been shipped through logistics on December 14. In order to solve customer concerns, the company has established a perfect after-sales service system: commitment to the machine enjoy standard quality assurance policy, professional after-sales team will respond to customer installation guidance, maintenance consultation and other needs in a timely manner, to ensure that the equipment quickly put into use. In addition, in the whole process of production, the salesman Li Haoran keeps communicating with the customers, synchronizing the production progress and the stock situation, so that the customers can grasp the order dynamics in real time.

As a professional manufacturer in the field of filtration equipment, Shanghai Junyi always takes customer needs as the core, and ADAPTS to the filtration needs of different industries and different scenes with the customization ability of “accurate design, quality production and efficient service”. The successful delivery of the customized basket filter in Suzhou not only accumulated the practical experience of “sketch transformation + custom production”, but also consolidated the company’s competitiveness in the domestic industrial filtration market. In the future, Jun Yi will continue to polish the design and production technology, optimize the customized service process, and provide more customers with accurate adaptation and reliable quality filtration equipment solutions.

Post time: Dec-05-2025