I. Customer Requirements

Material: CDEA (Coconut oil fatty acid diethanolamide), high viscosity (2000 centipoise).

Flow rate: 5m³/h.

Filtration objective: Improve color quality and reduce tar residue.

Filtration accuracy: 0.45 microns.

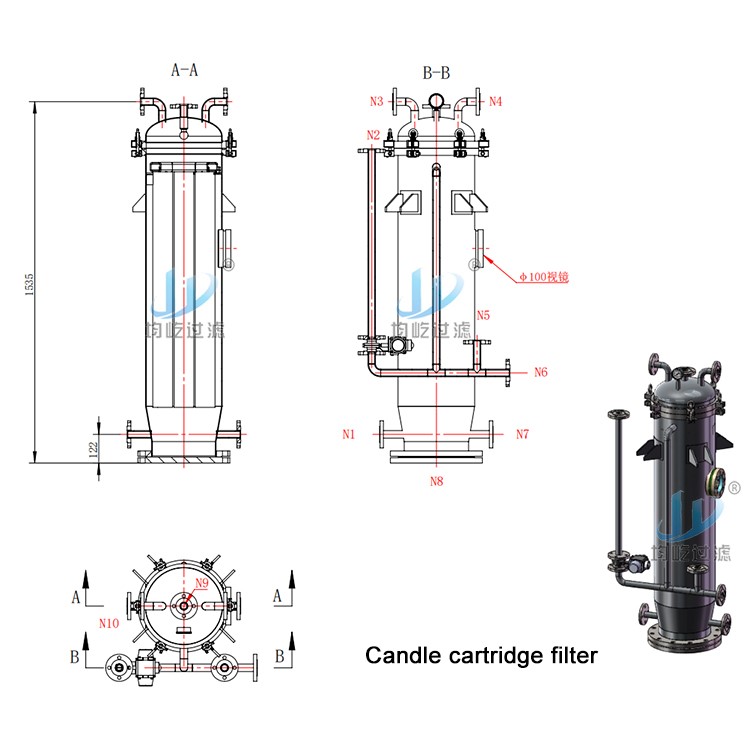

Ii. Advantages of Candle Filters

Suitable for high-viscosity liquids: The filter element structure provides a large filtration area and reduces flow resistance.

Filter AIDS (such as activated carbon, diatomite) can be added:

Improve color and adsorb impurities.

Form a filter cake layer to enhance filtration efficiency.

Manual operation, low cost: No electricity required, simple maintenance, suitable for small-scale production.

304 stainless steel material: Resistant to weakly acidic materials, with high cost performance.

Iii. Working Principle

Pre-coated filter aid: Forms a filter layer to enhance the ability to retain impurities.

Filtration: The liquid passes through the filter element, and impurities are intercepted by the filter cake layer.

Residue removal: Compressed air is used for reverse blowing to remove the filter cake and restore the filtration capacity.

Iv. Summary

Candle filters can effectively handle high-viscosity CDEA stock solutions, enhance color and purity, and have the advantages of simple operation and low cost. They are ideal filtration solutions.

Post time: May-17-2025