Recently, Shanghai Junyi Filter Equipment Co., Ltd. successfully completed the preparation of the special order (Contract No.: JY20251203GL-2, Order No.: 1626#) for the Saudi customer, relying on its precise adaptation to special working conditions and mature cross-border delivery experience. The XMY8-500 model chamber filter press customized for this customer is specifically designed for the sludge cleaning of zinc phosphate medium, with material selection suitable for a working temperature of 75℃ and neutral conditions, combined with an efficient solid-liquid separation design and comprehensive export guarantee services, once again demonstrating Junyi’s professional strength in the field of industrial filter equipment customization and international cooperation.

Precise Adaptation to Working Conditions: Solving the Problem of Separating High-Temperature Neutral Medium

In the production process of the Saudi customer, it is necessary to regularly clean the sludge from the liquid containing zinc phosphate. The medium is stable and neutral (pH value 6.0-7.5), with a working temperature of 75℃. The equipment is required to process 17m³ of material every 12 hours and meet the intermittent operation requirement once a week. The customer has three core demands: first, the equipment material must be suitable for high-temperature neutral medium to ensure corrosion resistance and no leakage; second, the solid-liquid separation efficiency must be stable to ensure the sludge cleaning effect; third, the operation must be convenient, suitable for the on-site working environment, and the company must provide trial operation verification and comprehensive export support services.

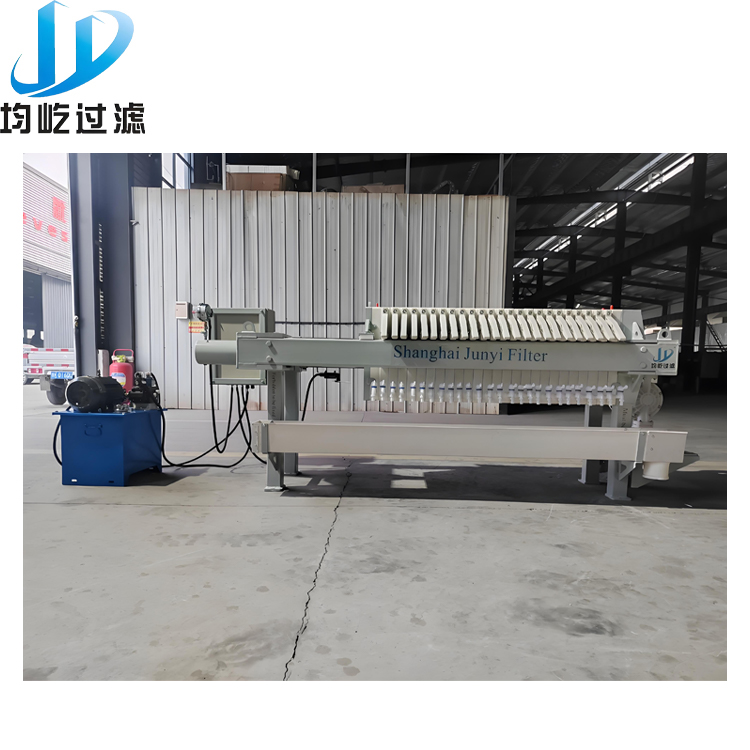

After receiving the demand, Junyi’s technical team quickly carried out the working condition analysis and solution customization: for the high-temperature neutral characteristics of the zinc phosphate medium, PP material was selected as the core material for the filter plate and filter cloth to avoid equipment wear caused by long-term contact with the medium; combined with the processing capacity of 17m³/12h, the XMY8-500 model chamber structure was determined, equipped with a hydraulic 120 oil cylinder and manual plate-pulling design, balancing separation efficiency and operation convenience; in response to the customer’s special requirements for equipment verification and export, services such as trial operation testing, photo and video retention, and custom nameplate were clearly included. After the technical solution was confirmed by the customer, production and preparation were quickly initiated.

Precision Customization: Quality Ensures Core Competitiveness

To ensure the stable and reliable operation of the equipment under high-temperature conditions, Junyi implemented meticulous control throughout the production process, strictly following the customization standards from component selection to complete machine assembly:

- Core structure adaptation: Adopting a 500-type chamber design with clear flow, equipped with 19 intermediate filter plates of 50mm thickness made of PP material and 2 head and tail plates, with filter plate dimensions of 500×500mm, and PP-750B model filter cloth (19+1 sets), precisely matching the separation requirements of zinc phosphate sludge, ensuring efficient and thorough solid-liquid separation;

- Precise matching of materials and parameters: The entire machine frame structure is stable, with a plastic water tank for collecting filtrate, and the equipment is compatible with 380V, 60HZ three-phase voltage, fully meeting the local industrial power standards in Saudi Arabia; the inlet and outlet and connection structure design fully consider the adaptability to on-site pipelines, ensuring installation convenience;

- Comprehensive quality inspection: After assembly, the equipment undergoes special trial operation tests, focusing on verifying the stability of the hydraulic cylinder operation, the sealing of the filter plates, and the clarity of the filtrate, and simultaneously recording the trial operation video for retention; all components are inspected for appearance and function, ensuring that the equipment can be put into use immediately upon unpacking, meeting the customer’s payment and subsequent installation requirements

- Cross-border Protection: Comprehensive Delivery Assurance

To ensure the timely and safe delivery of the equipment to the Saudi customer, Junyi established a special order service mechanism, fully controlling the entire delivery process.

- Efficient inventory response: The production department prioritizes the allocation of PP raw materials and core component resources, strictly adhering to the technical plan to advance the processing of the frame, customization of filter plates and cloths, and assembly of the complete machine. Within the stipulated period, one XMY8-500 type filter press and a full set of accessories are produced and stocked, precisely locking in the delivery date of January 20, 2026.

- Professional export guarantee: Specialized export wooden crates are used for packaging, with additional reinforcement and protection for vulnerable parts such as hydraulic cylinders, filter plates, and valves to prevent damage during cross-border transportation. Simultaneously, installation manuals, technical parameter sheets, and other supporting documents are organized to facilitate customer customs clearance and ensure a worry-free cross-border transportation process.

- Detail-oriented to meet demands: Customized equipment nameplates are strictly produced according to customer requirements, and the entire production, assembly, and test run process is recorded with high-definition photos and test run videos, providing support for customers to retain evidence and prompt payment of the final installment. Sales representatives keep customers updated on inventory progress and logistics arrangements in real time, responding promptly to customer inquiries to ensure customers are always informed of order status.

As a professional manufacturer specializing in customized industrial filtration equipment, Shanghai Junyi has always focused on the individualized working conditions of different industries, with the core advantages of “precise adaptation to working conditions, stable and reliable quality, and considerate full-service”. This has earned it wide recognition from global customers. The successful stocking of the XMY8-500 type filter press order from Saudi Arabia not only demonstrates the company’s in-depth understanding of high-temperature neutral medium separation scenarios but also highlights Junyi’s mature capabilities in cross-border equipment customization and export delivery services. In the future, Junyi will continue to delve into specific working conditions, optimize filtration solutions, and provide more targeted and efficient filtration equipment and services to global customers, continuously expanding its international cooperation network.

Post time: Jan-08-2026