The customer uses a mixed solution of activated carbon and salt water as the raw material. The activated carbon is used for adsorbing impurities. The total filtration volume is 100 liters, with the content of solid activated carbon ranging from 10 to 40 liters. The filtration temperature is 60 to 80 degrees Celsius. It is hoped to increase the air blowing device to reduce the moisture content of the filter cake and obtain as dry a filter cake as possible.

According to the customer’s process requirements, after comprehensive evaluation, the following configuration was selected:

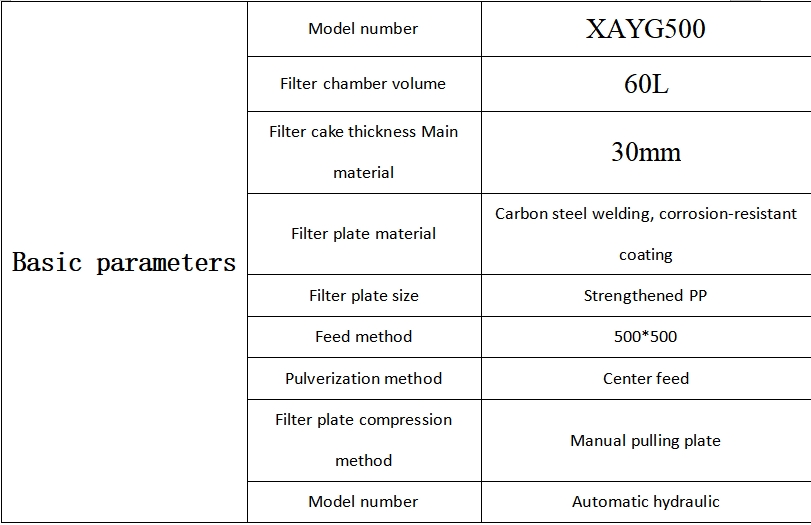

Machine: Diaphragm filter press

Filter chamber volume: 60L

Filter press frame material: Carbon steel welding, corrosion-resistant coating

Core function: Efficient filtration, thorough squeezing, effectively reducing the moisture content of the filter cake.

This solution fully meets the customer’s requirements. It uses a diaphragm filter press, which is suitable for solid-liquid separation and can effectively separate activated carbon solid particles from salt water. The squeezing effect of the diaphragm can make the filter cake structure more compact, avoiding the loss and scattering of activated carbon particles caused by the loose filter cake when the ordinary filter press discharges. When using the diaphragm filter press to treat activated carbon suspensions, the recovery rate can reach over 99%, especially suitable for the recovery scenarios of high-value activated carbon. For high-concentration activated carbon suspensions, the diaphragm filter press can directly receive the feed without pre-dilution, reducing the process steps and energy consumption. During the squeezing process, the flexible pressure of the diaphragm acts uniformly on the filter cake, without damaging the pore structure of the activated carbon, thus maintaining its adsorption performance. Because the diaphragm squeezing can significantly reduce the moisture content of the filter cake, the energy consumption of the subsequent drying process can be reduced by 30% – 40%.

Post time: Jul-05-2025