Project Background

A large mining enterprise is facing challenges in tailings treatment during its production process. Traditional equipment is unable to meet its requirements for high efficiency and low energy consumption in the process of dewatering. The high moisture content of tailings leads to extremely high transportation costs, and frequent equipment maintenance significantly affects the normal production schedule.

Solution

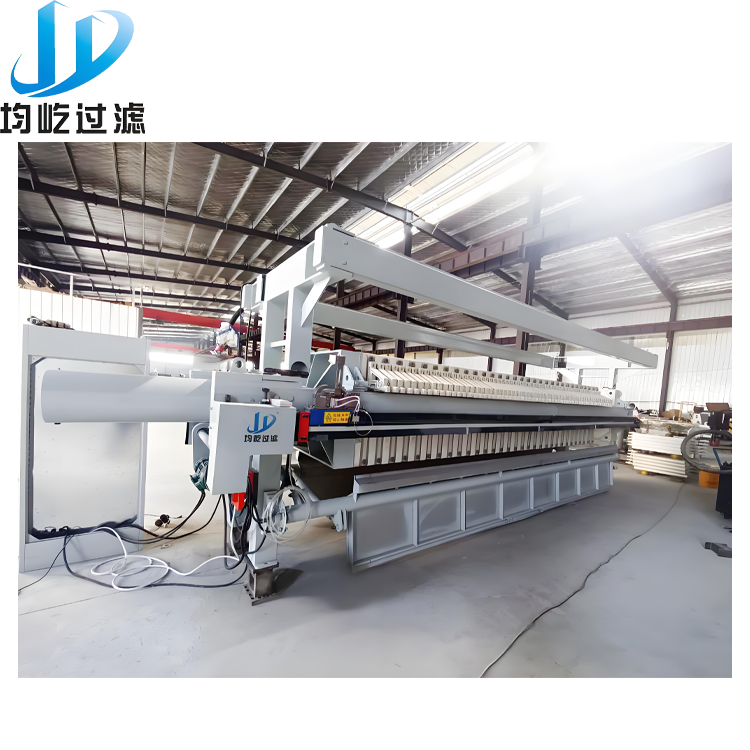

We provided them with a diaphragm filter press solution featuring automatic water flushing function:

By adopting the high-pressure diaphragm secondary pressing technology, the dehydration efficiency has been significantly improved.

Configure an intelligent water flushing system to achieve automatic cleaning of the filter cloth.

Optimize the material of the equipment and enhance its corrosion resistance performance.

Implementation results

After the project was implemented, remarkable achievements were made:

The moisture content of the tailings has been significantly reduced, which directly leads to a decrease in transportation and processing costs.

The automated water flushing system reduces the frequency of manual maintenance.

The operational stability of the equipment has been enhanced, ensuring the continuity of production.

The overall energy consumption has significantly decreased, achieving the goal of energy conservation and emission reduction.

Customer feedback

The customer highly commends the performance of the equipment, particularly praising its stable operation and significant energy-saving effect. The implementation of this equipment not only solves the current tailings treatment problem but also provides a reliable guarantee for the subsequent expansion plan.

Project Significance

This case has fully demonstrated the applicability of the diaphragm filter press in the mining industry. Its outstanding dehydration performance and intelligent features have provided a new technical solution for the industry. The successful implementation of this project has also offered valuable experience for tailings treatment under similar working conditions.

Post time: Aug-15-2025