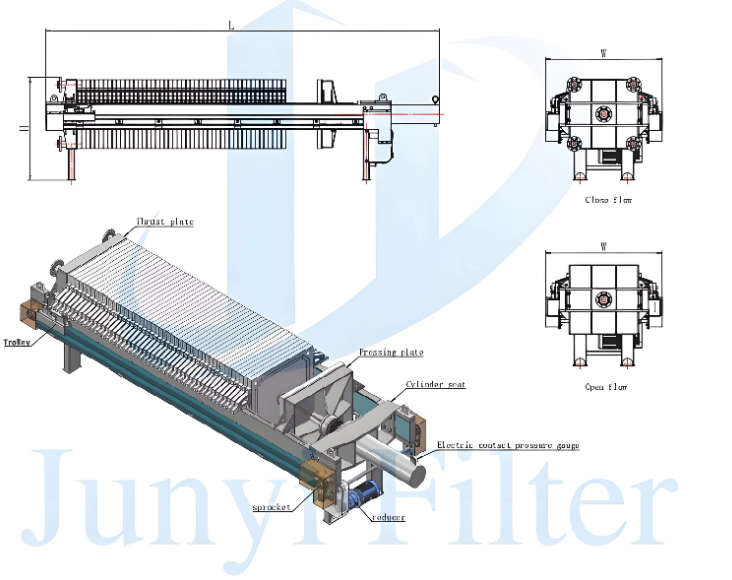

Automatic Discharge Chamber Filter Press Machine for Solid Liquid Separation

Main Structure and Components

1. Rack Section Including the front plate, rear plate and main beam, they are made of high-strength steel to ensure the stability of the equipment.

2. Filter plate and filter cloth The filter plate can be made of polypropylene (PP), rubber or stainless steel, which has strong corrosion resistance; the filter cloth is selected according to the characteristics of the materials (such as polyester, nylon).

3. Hydraulic System Provide high-pressure power, automatically compress the filter plate (the pressure can usually reach 25-30 MPa), with excellent sealing performance.

4. Automatic Plate Pulling Device Through motor or hydraulic drive, the filter plates are precisely controlled to be pulled apart one by one, enabling rapid discharging.

5. Control System PLC programming control, supporting touchscreen operation, allowing setting of parameters such as pressure, time, and cycle count.

Core Advantages

1. High-efficiency Automation: No manual intervention throughout the process. The processing capacity is 30% – 50% higher than that of traditional filter presses.

2. Energy conservation and environmental protection: The moisture content of the filter cake is low (in some industries, it can be reduced to below 15%), thereby reducing the cost of subsequent drying; the filtrate is clear and can be reused.

3. High durability: Key components are designed with anti-corrosion features, ensuring long service life and easy maintenance.

4. Flexible Adaptation: Supports various designs such as direct flow, indirect flow, washable, and non-washable, meeting different process requirements.

Equipment schematic diagram

Programmed automatic pulling plate chamber filter presses is not manual operation, but a key start or remote control and achieve full automation. Junyi’s chamber filter presses are equipped with an intelligent control system with an LCD display of the operating process and a fault warning function. At the same time, the equipment adopts Siemens PLC automatic control and Schneider components to ensure the overall operation of the equipment. In addition, the equipment is equipped with safety devices to ensure safe operation.

Application fields

1.Chemical Industry: Pigments, dyes, catalyst recovery.

2.Mining: Tailings dewatering, extraction of metal concentrates.

3.Environmental protection: Municipal sludge and industrial wastewater treatment.

4.Food: Juice clarified, starch dehydrated.

How to choose the right model?

- What is the liquid that needs filtering?

2. What is the flow rate?

3. Temperature/PH value?

4. What are the main solid impurities that need to be filtered from the liquid? What is their content?

We can make recommendations based on this information.