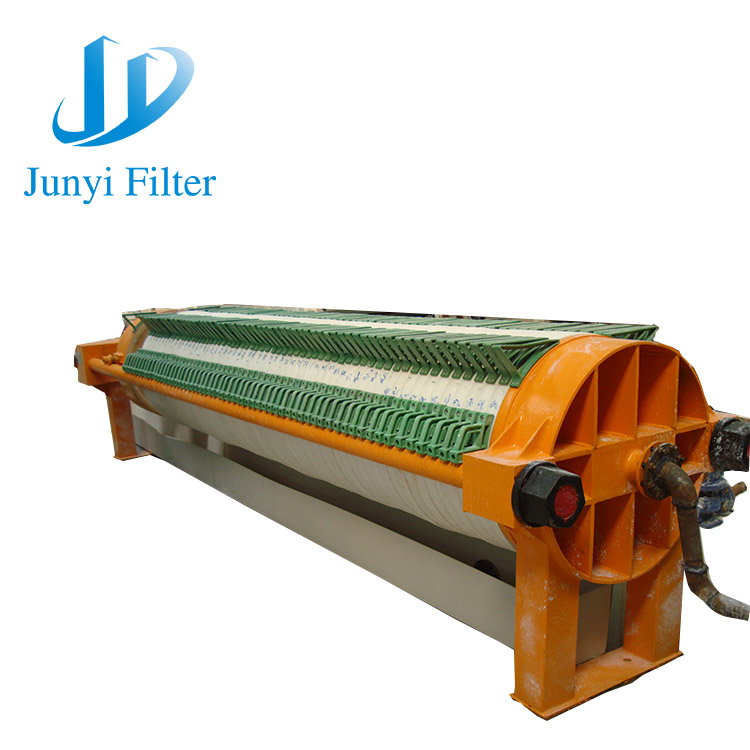

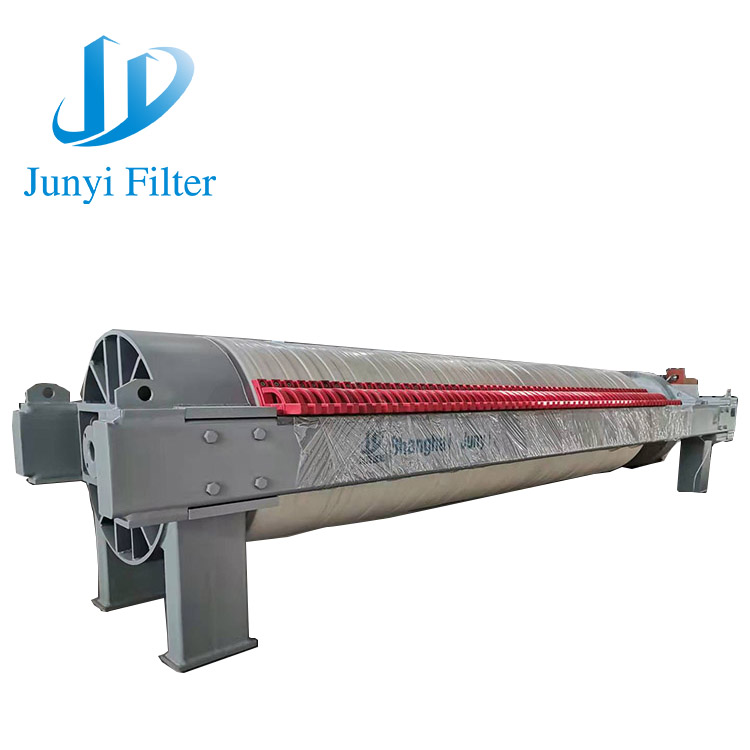

High efficiency and energy saving circulating circular filter press with low water content in filter cake

Product features of the circular filter press

Compact structure, space-saving – With a circular filter plate design, it occupies a small area, is suitable for working conditions with limited space, and is also convenient for installation and maintenance.

High-efficiency filtration and excellent sealing performance – The circular filter plates, in combination with the hydraulic pressing system, create a uniform high-pressure filtration environment, effectively enhancing the dehydration rate, reducing the moisture content of the filter cake, and featuring outstanding sealing performance to prevent material leakage.

High degree of automation – Equipped with a PLC control system, it realizes automatic pressing, feeding, filtration, unloading and cleaning, reducing the intensity of manual operation and improving production efficiency.

Applicable fields:

It is suitable for high-standard solid-liquid separation in fine chemicals, food, environmental protection and other industries, especially for material handling with high requirements for sealing and filtration accuracy.

Filtration pressure: 2.0Mpa

Liquid discharge mode – open flow: the bottom of the filter plate out of the water supporting the use of the receiving tank. Or matching liquid catching flap + water catching tank;

Selection of filter cloth material: PP non-woven cloth.

Surface treatment of frame: PH value neutral or weak acidic or alkaline, filter press frame surface sandblasting, spraying primer plus anticorrosive paint; PH value strong acidic or alkaline, filter press frame surface sandblasting, spraying primer, surface wrapped with stainless steel or PP plate.

Circular filter press operation: automatic hydraulic compression, automatic pulling open of the filter plate, vibration of the filter plate to unload the cake, automatic water flushing system of the filter cloth;