Product features

1. Filtering does not require filter cloth or filter paper, reducing the cost of filtration.

2. The entire process is carried out in a sealed manner, which is more environmentally friendly and there is no material loss.

3. The equipment adopts a vibration discharge method, reducing the labor intensity of workers and enabling continuous operation.

4. The pneumatic valve discharges the material, reducing the labor intensity of workers.

5. The materials in the liquid are pressed into cakes or activated carbon is filtered directly or through dehydration filtration.

6. The leaf filter machine can completely replace the plate and frame filter machine and is the preferred equipment.

7. The unique design structure is small in size; the filtration efficiency is high; the filtrate transparency is good and the fineness is high; there is no material loss.

8. The operation, maintenance and cleaning of this equipment are simple.

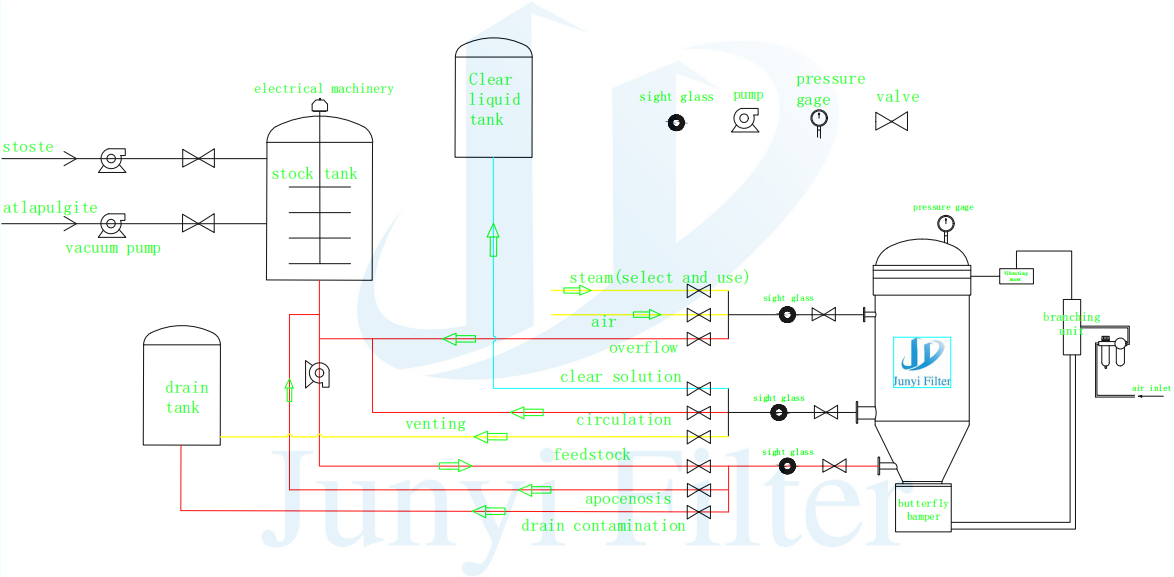

Working principle

1.Pressure filtration: The material is pumped in. Under the pressure, the liquid passes through the filter screen, while the solids are retained and form a filter cake. The clear liquid is discharged.

2. Washing (optional): Introduce washing solution to penetrate the filter cake and remove impurities or recover the active ingredients.

3. Drying (optional): Introduce gas to blow dry the filter cake and reduce the liquid content.

4. Vibration discharge: The vibrating blades cause the dry filter cake to fall off and be discharged, completing the cycle.

Core essence: An intermittent filtration cycle carried out in a sealed container, which uses pressure differences to drive separation and also enables washing and drying functions.

In order to provide you with the most accurate quotations and technical solutions, we need to know the following information:

1.What materials do you want to filter? (Name, characteristics)

2.What are the solids in the materials? And what is their approximate content?

3. What are the approximate temperatures and viscosities of the materials?

4. What kind of filtering effect do you hope to achieve? (Is it a rough clarification or a highly purified result?)

5. What is the expected processing volume? (How many cubic units per hour or per day?)

Blade filter application industries

1 Petroleum and chemical industry: diesel, lubricants, white oil, transformer oil, polyether

2 Base oils and mineral oils: Dioctyl ester, Dibutyl ester

3 Fats and oils: crude oil, gasified oil, winterised oil, bleached each

4 Foodstuffs: gelatine, salad oil, starch, sugar juice, monosodium glutamate, milk, etc.

5 Pharmaceuticals: hydrogen peroxide, vitamin C, glycerol, etc.

6 Paint: varnish, resin paint, real paint, 685 varnish, etc.

7 Inorganic chemicals: bromine, potassium cyanide, fluorite, etc.

8 Beverages: beer, juice, liquor, milk, etc.

9 Minerals: coal chips, cinders, etc.

10 Others: air and water purification, etc.

Previous:

Automatic Filter Press for Recycling and Recovery of Useful Materials

Next:

Automatic Discharge Chamber Filter Press Machine for Solid Liquid Separation