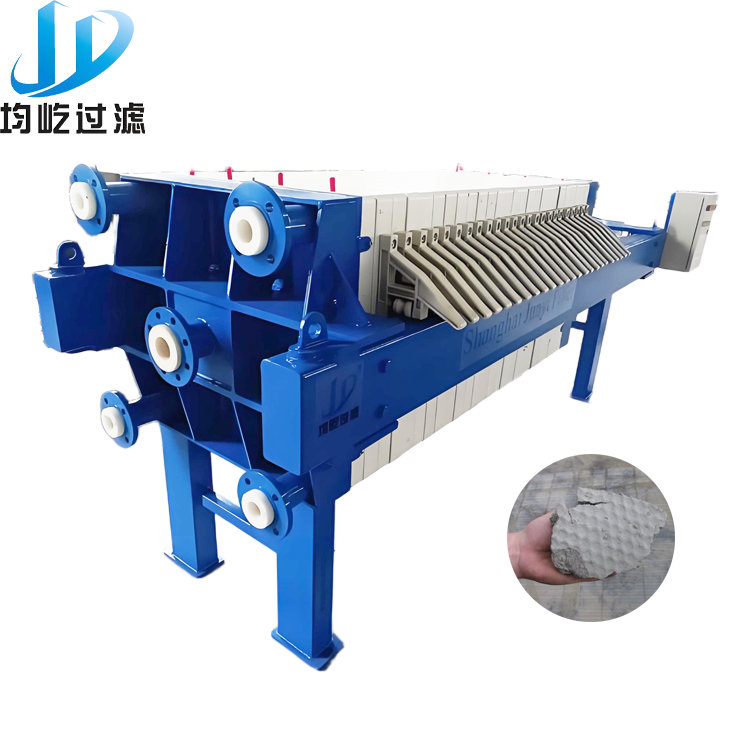

Directly Supplied by the Factory Automatic Hydraulic Filter Press for Continuous Operation

Key Features

1.High-strength box-type structure design, with excellent pressure resistance performance

2.Fully automatic PLC control system, enabling one-click operation

3.Modular design, with simple and efficient maintenance.

4.Multiple safety protection devices ensure reliable operation

5.Low energy consumption design, with economical operating costs

6.Selection of corrosion-resistant materials, suitable for harsh working conditions

Basic workflow

The box-type filter press achieves solid-liquid separation through pressure drive. Its working process can be divided into four main stages:

1.Compression stage: The hydraulic system drives the compression plate, causing the filter plate group to tightly close and form a sealed filtration chamber.

2.Feed filtration: The slurry is injected into the filter chamber through the feed pump, and solid-liquid separation is achieved under the pressure effect.

3.Pressurized dehydration: Further reducing the moisture content of the filter cake through membrane squeezing or high-pressure gas.

4.Discharge cleaning: Remove the filter cake by opening the filter plate, and clean the filter cloth if necessary.

How to choose the right model?

- What is the liquid that needs filtering?

2. What is the flow rate?

3. Temperature/PH value?

4. What are the main solid impurities that need to be filtered from the liquid? What is their content?

We can make recommendations based on this information.