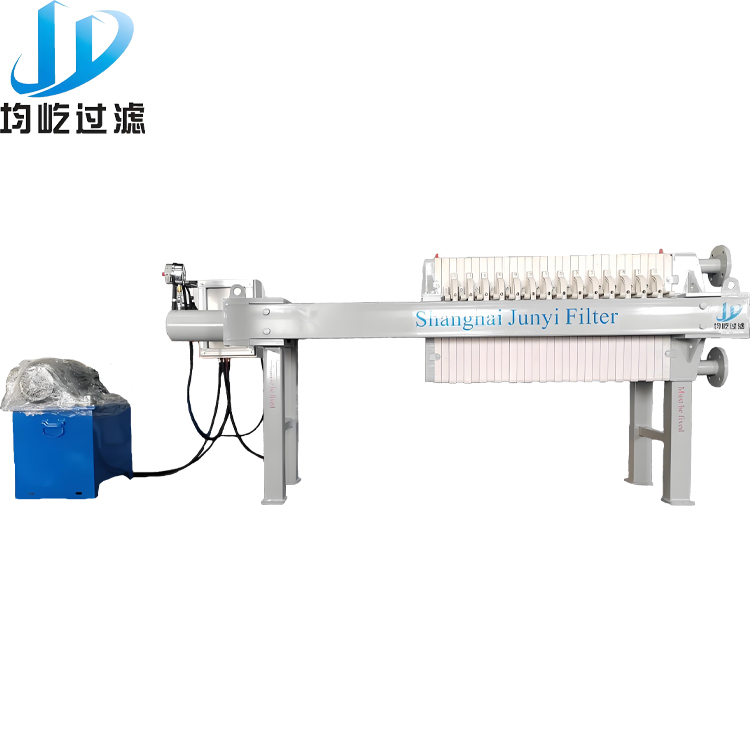

Efficient Automatic Plate and Frame Filter Press for Chemical Industry Applications

Product Overview

The Plate and Frame Filter Press is a highly efficient solid-liquid separation system widely used in industries such as chemical, food processing, environmental (sludge dewatering), and mining.

It utilizes high-pressure filtration to separate solid particles from liquid suspensions, producing low-moisture filter cakes for various industrial applications.

Why choose a plate and frame filter press?

✔ Wide adaptability: Can handle high-viscosity and high-solid-content materials.

✔ Low cake moisture content: Significantly reduces subsequent drying or disposal costs.

✔ Corrosion-resistant design: Made of PP, stainless steel, etc., can withstand acidic, alkaline, and high-temperature environments.

✔ Automation options: PLC control, automatic discharge, reduces manual operations.

Core advantage

✅ High Efficiency – Robust plate and frame structure ensures fast filtration and large processing capacity.

✅ Low Moisture Content – Filter cake moisture can be as low as 30%~50%, reducing drying costs.

✅ Corrosion-Resistant – Filter plates available in PP, reinforced polypropylene, or stainless steel for harsh chemical environments.

✅ Automated Operation – Optional PLC control for automatic clamping, filtration, and cake discharge.

✅ Energy-Saving & Eco-Friendly – Low power consumption, clear filtrate for recycling, reduced wastewater load.

Main application scenarios

This equipment is a fundamental piece of equipment for handling various industrial solid-liquid separation requirements, and is particularly suitable for the following fields:

1. Environmental Engineering: Sludge dewatering for municipal sewage treatment plants; Industrial sludge treatment in industries such as dyeing, papermaking, electroplating, and chemical manufacturing.

2. Chemical industry: Filtration, washing and extraction of pigments, dyes, etc.

3. Mining and Metallurgy: Dewatering of metal tailings (such as bauxite, red mud), concentrates, and waste residues from smelting processes.

4. Food and Biotechnology Engineering: Solid-liquid separation of starch, yeast, soy sauce, fruit juice, enzyme preparations and fermentation liquids.

5. Other fields: River dredging, dehydration operations for ceramic raw materials, quartz sand and other materials.

Write your message here and send it to us