Factory Supply Manual Hydraulic Filter Press for Solid-Liquid Separation

Product features

✅ Manual hydraulic drive: Utilizes a manual oil pump to provide pressure, without the need for electricity. Suitable for environments without power supply or for mobile operations.

✅ High-strength structure: The frame is welded with high-quality steel, resistant to corrosion and deformation, ensuring long-term stable operation.

✅ High-efficiency filtration: Uses PP (polypropylene) or reinforced polypropylene filter plates, resistant to acids and alkalis, and high-temperature resistant, with high filtration accuracy.

✅ Flexible adjustment: The manual hydraulic system can precisely control the pressing force, meeting the filtration requirements of different materials.

✅ Economical and energy-saving: No need for electric drive, reducing energy consumption, suitable for enterprises with limited budgets.

✅ Easy maintenance: Simple structure, convenient filter plate replacement, low maintenance cost.

✅ Multiple specifications available: Customizable filter area, filter plate size and material according to customer requirements.

Operation Procedure

Loading: Place the filter cloth on the filter plate and then shut down the filter press.

Press down: Manually operate the hydraulic pump to cause the filter plate to be pressed down.

Feed: The material to be filtered is pumped in. The liquid passes through the filter cloth and flows out, while the solids remain inside the filter chamber.

Discharge: After the filtration process is completed, release the hydraulic system and remove the filter plates one by one to discharge the residue.

Cleaning: Clean the filter cloth and filter plates, and prepare for the next round of filtration.

Application fields

1.Chemical industry: Solid-liquid separation for pigments, dyes, titanium dioxide, calcium carbonate, etc.

2.Mining industry: Dewatering of tailings, filtration of metal concentrates, treatment of coal sludge.

3.Environmental protection industry: Sewage treatment, sludge dewatering, river dredging.

4.Food industry: Filtration of starch, soy sauce, fruit juice, edible oil.

5.Metallurgical industry: Dewatering of metal smelting slag, alumina, zinc powder.

How to choose the right model?

- What is the liquid that needs filtering?

2. What is the flow rate?

3. Temperature/PH value?

4. What are the main solid impurities that need to be filtered from the liquid? What is their content?

We can make recommendations based on this information.

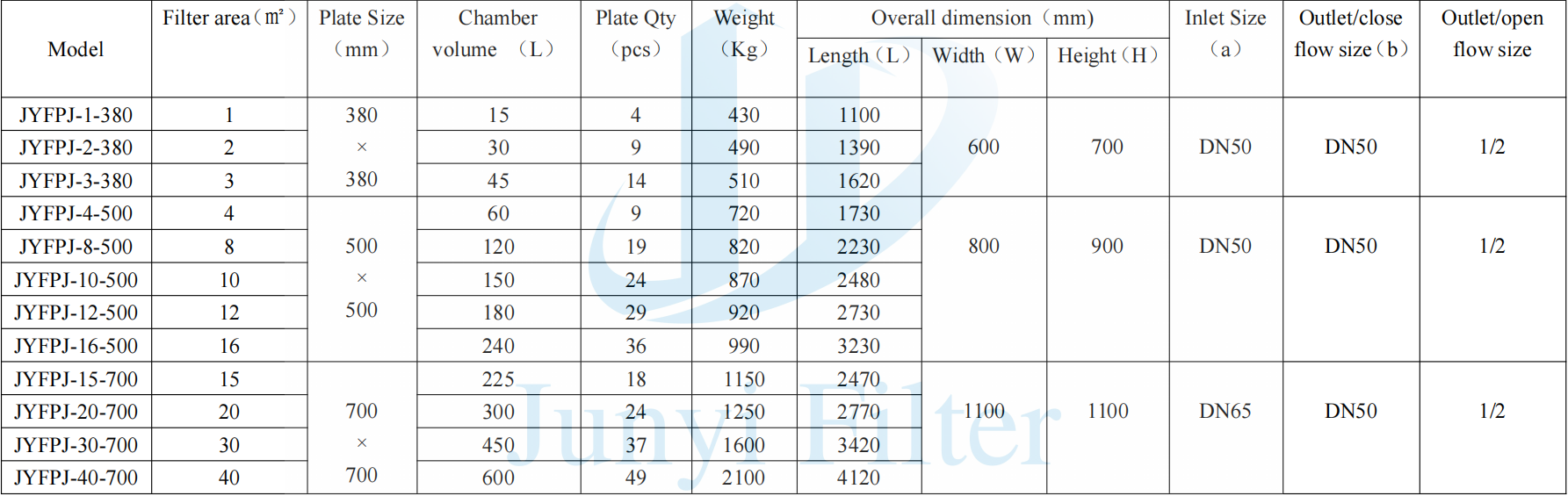

Parameters

Write your message here and send it to us