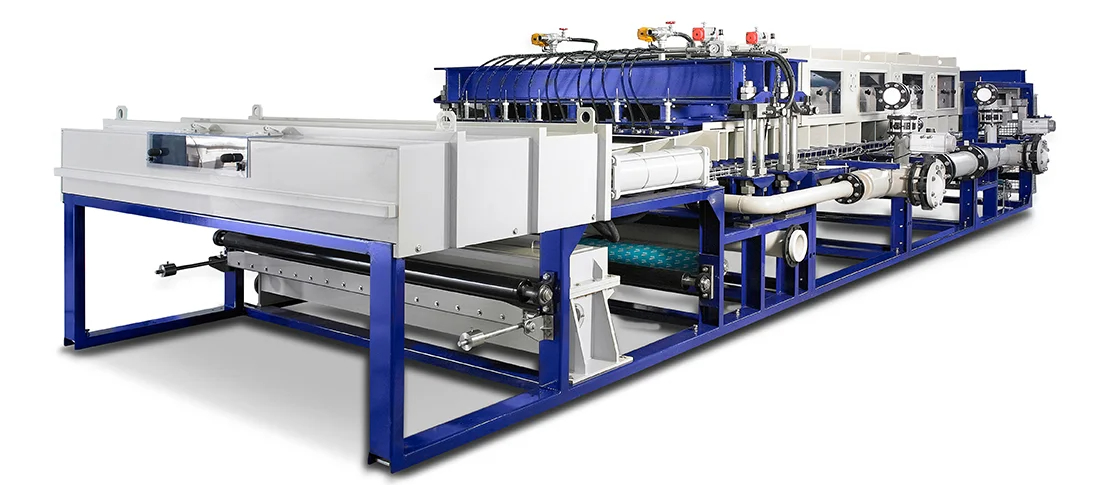

High quality dewatering machine belt filter press

1. Material of the main structure : SUS304/316

2. Belt : Has a long service life

3. Low power consumption, slow-speed of revolution and low noise

4. Adjustment of belt: Pneumatic regulated, ensures the stability of the machine

5. Multi-point safety detection and emergency stop device:improve the operation.

6. The design of the system is obviously humanized and provides convenience in operation and maintenance.

printing and dyeing sludge, electroplating sludge,

papermaking sludge, chemical sludge, municipal sewage sludge,

mining sludge, heavy metal sludge, leather sludge,

drilling sludge, brewing sludge, food sludge,

Write your message here and send it to us