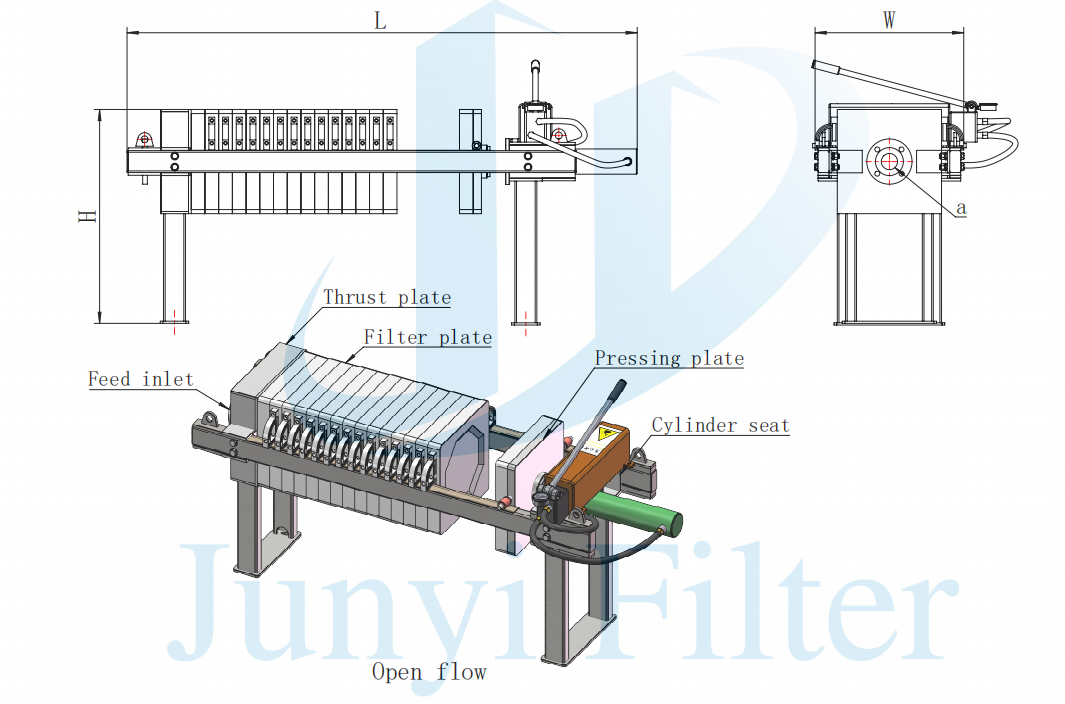

Manual Hydraulic Cylinder Chamber Filter Press for Sludge Dewatering

Product Features

✅ Manual hydraulic drive: Utilizes a manual oil pump to provide pressure, eliminating the need for electricity. Suitable for environments without power supply or for mobile operations.

✅ High-strength structure: The frame is welded with high-quality steel, resistant to corrosion and deformation, ensuring long-term stable operation.

✅ High-efficiency filtration: Uses PP (polypropylene) or reinforced polypropylene filter plates, resistant to acids and alkalis, and high-temperature resistant, with high filtration accuracy.

✅ Flexible adjustment: The manual hydraulic system can precisely control the pressing force, meeting the filtration requirements of different materials.

✅ Energy-saving and economical: No electricity is required for driving, reducing energy consumption, suitable for enterprises with limited budgets.

✅ Easy maintenance: The structure is simple, and filter plate replacement is convenient, with low maintenance costs.

✅ Multiple specifications available: Customizable filter area, filter plate size, and material can be tailored according to customer needs.

Operation Procedure

Loading: Place the filter cloth on the filter plate and then shut off the filter press.

2. Compression: Manually operate the hydraulic pump to compress the filter plate.

3. Feed: The material to be filtered is pumped in. The liquid passes through the filter cloth and flows out, while the solids remain inside the filter chamber.

4. Discharge: After the filtration process is completed, release the hydraulic system and remove the filter plates one by one to discharge the residue.

5. Cleaning: Clean the filter cloth and filter plates, and prepare for the next round of filtration.

Application fields

Chemical industry: Solid-liquid separation for pigments, dyes, titanium dioxide, calcium carbonate, etc.

Mining industry: Dewatering of tailings, filtration of metal concentrates, treatment of coal sludge.

Environmental protection industry: Sewage treatment, sludge dewatering, river dredging.

Food industry: Filtration of starch, soy sauce, fruit juice, edible oil.

Metallurgical industry: Dewatering of metal smelting slag, alumina, zinc powder.