New products Fully Automatic Hydraulic Filter Press with Secondary Pulling Plates System

Main structural components

1. Frame section High-strength steel structure frame, ensuring the stability and pressure-bearing capacity of the equipment. The hydraulic cylinder drives the filter plate group to be pressed and released.

2. Filter plate and filter cloth Filter plate material: reinforced polypropylene (PP), rubber, stainless steel, etc. Resistant to corrosion and high temperature. Secondary opening design: The filter plates are alternately opened in two groups to prevent the filter cake from sticking together as a whole, ensuring a more thorough discharge.

3. Hydraulic System A high-pressure hydraulic pump, control valve and cylinder are combined to provide stable clamping force and support automatic pressure retention. Optional PLC control is available, enabling fully automated processes of pressing, opening and discharging.

4. Automatic Plate Pulling System Electric or hydraulic-driven mechanical hands sequentially pull out the filter plates, and are assisted in discharging by vibration or scrapers.

5. Liquid receiving device The design of the collection tray or pipeline prevents the filtrate from spilling out and keeps the working environment clean.

Product Features

1. Efficient Discharge: The double-pull design addresses the issue of difficult removal of sticky filter cakes, thereby reducing the cycle time.

2. High degree of automation: Supports PLC control, enabling the entire process of pressing, filtering, opening, and discharging to be fully automated.

3. Energy conservation and environmental protection: The filtrate recovery rate is high, reducing material waste; the sealed design prevents odor leakage.

4. Convenient maintenance: The filter plate can be replaced separately, and the hydraulic system is equipped with overload protection.

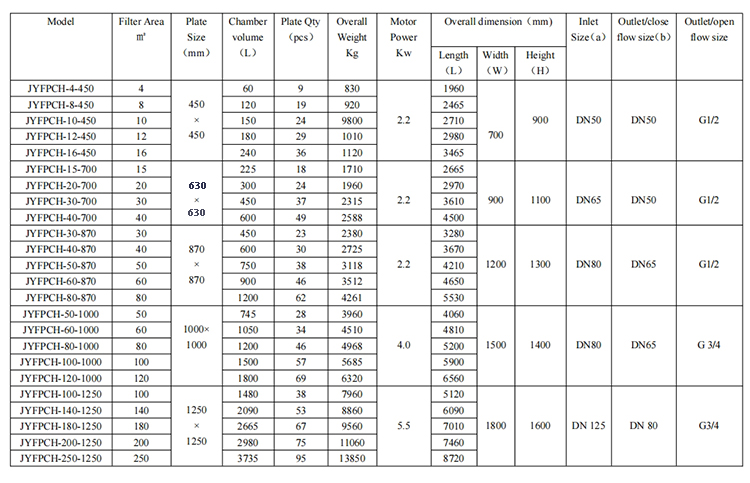

5. Flexible configuration: The number, size and material of the filter plates can be customized according to your needs (common specifications: 630 – 2000mm).

Working principle

1. Pressurization stage:The material is pumped into the filter chamber, where a filter cake is formed under high pressure, and the liquid passes through the filter cloth and is discharged.

2. Second-stage discharge opening: First opening: The filter plate is divided into two parts, for the initial separation of the filter cake. Second opening: Each group of filter plates is opened one by one. The filter cake falls off due to gravity or with the help of auxiliary devices.

3. Continuous operation: Automatic filter cloth cleaning (optional), filter plates are re-pressed, and the process moves to the next cycle.

- Parameter

Application Fields

Chemical Industry: Pigment, dye, and catalyst filtration.

Mining: Tailings dewatering, concentrate extraction.

Environmental protection: sludge dewatering, sewage treatment.

Food: Starch, clarification of fruit juice.