High-Pressure Diaphragm Filter Press – Low Moisture Cake, Automated Sludge Dewatering

Product Introduction

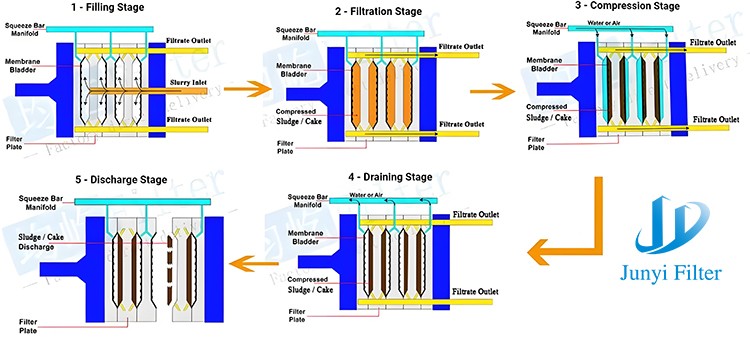

The membrane filter press is an efficient solid-liquid separation equipment.

1.Environmental protection industry (wastewater treatment and sludge dewatering)

Municipal wastewater treatment plant:

Used for concentrating and dewatering sludge (such as activated sludge, digested sludge), it can reduce the moisture content from 98% to below 60%, making it easier for subsequent incineration or landfill.

Industrial wastewater treatment:

Dewatering treatment of high-moisture and high-pollutant sludges such as electroplating sludge, dyeing sludge, and papermaking sludge.

Separation of heavy metal precipitates from wastewater in the chemical industrial park.

River/lake dredging: The silt is rapidly dehydrated, reducing transportation and disposal costs.

Advantages:

✔ Low moisture content (up to 50%-60%) reduces disposal costs

✔ Corrosion-resistant design can handle acidic and alkaline sludge

2. Mining and Metallurgy Industry

Tailings treatment:

Dewatering of tailings slurry from iron ore, copper ore, gold ore and other mineral processing, to recover water resources and reduce the land occupation of tailings ponds.

Dewatering of concentrate:

Improving the grade of the concentrate (such as lead-zinc ore, bauxite) makes it easier to transport and smelt.

Metallurgical slag treatment:

Solid-liquid separation of waste slags such as steel slag and red mud, and recovery of useful metals.

Advantages:

✔ The high-pressure extrusion results in a filter cake with a moisture content as low as 15%-25%

✔ The wear-resistant filter plates are suitable for high-hardness minerals

3. Chemical Industry

Fine Chemicals:

Washing and dehydration of powders such as pigments (Titanium Dioxide, Iron Oxide), dyes, calcium carbonate, kaolin, etc.

Fertilizers and pesticides:

Separation and drying of crystalline products (such as ammonium sulfate, urea).

Petrochemical industry:

Catalyst recovery, oil sludge treatment (such as oil sludge from oil refineries).

Advantages:

✔ Acid and alkali resistant material (PP, rubber lined steel) suitable for corrosive media

✔ Closed operation reduces toxic gas emissions

4. Food and Biotechnology Engineering

Starch Processing:

Drying and washing of corn and potato starch, using alternative centrifuges to reduce energy consumption.

Brewing industry:

Separation of yeast, amino acids, and antibiotic mycelium.

Beverage production:

Pressing and dehydration of beer mash and fruit residues.

Advantages:

✔ Made of food-grade stainless steel or PP material, meeting hygiene standards

✔ Low-temperature dehydration retains active ingredients