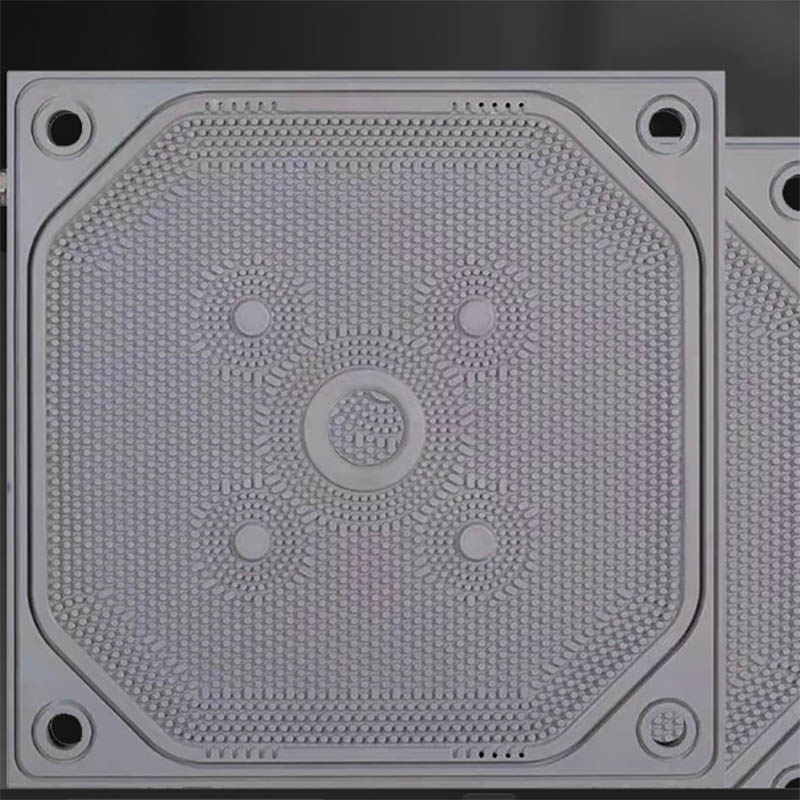

The diaphragm filter plate is composed of two diaphragms and a core plate combined by high-temperature heat sealing. An extrusion chamber (hollow) is formed between the membrane and the core plate, and external media (such as water or compressed air) is introduced into the chamber between the core plate and the membrane, causing the membrane to bulge and compress the filter cake in the chamber, achieving secondary extrusion dehydration of the filter cake.

✧ Product Features

1. The PP filter plate (core plate) adopts reinforced polypropylene, which has strong toughness and rigidity, improving the compression sealing performance and corrosion resistance of the filter plate;

2. The diaphragm is made of high-quality TPE elastomer, which has high strength, high resilience, and high-temperature and high-pressure resistance;

3. The working filtration pressure can reach 1.2MPa, and the pressing pressure can reach 2.5MPa;

4. The filter plate adopts a special flow channel design, which increases the filtration speed by about 20% and reduces the moisture content of the filter cake.

✧ Application Industries

Widelyusedinindustriessuchaschemical, pharmaceutical, food, metallurgy, oilrefining, clay, sewage treatment, coalpreparation, infrastructure, municipalsewage, etc.

✧ Filter Press Ordering Instructions

630mm×630mm; 800mm×800mm; 870mm×870mm; 1000mm×1000mm; 1250mm×1250mm; 1500mm×1500mm; 2000mm*2000mm