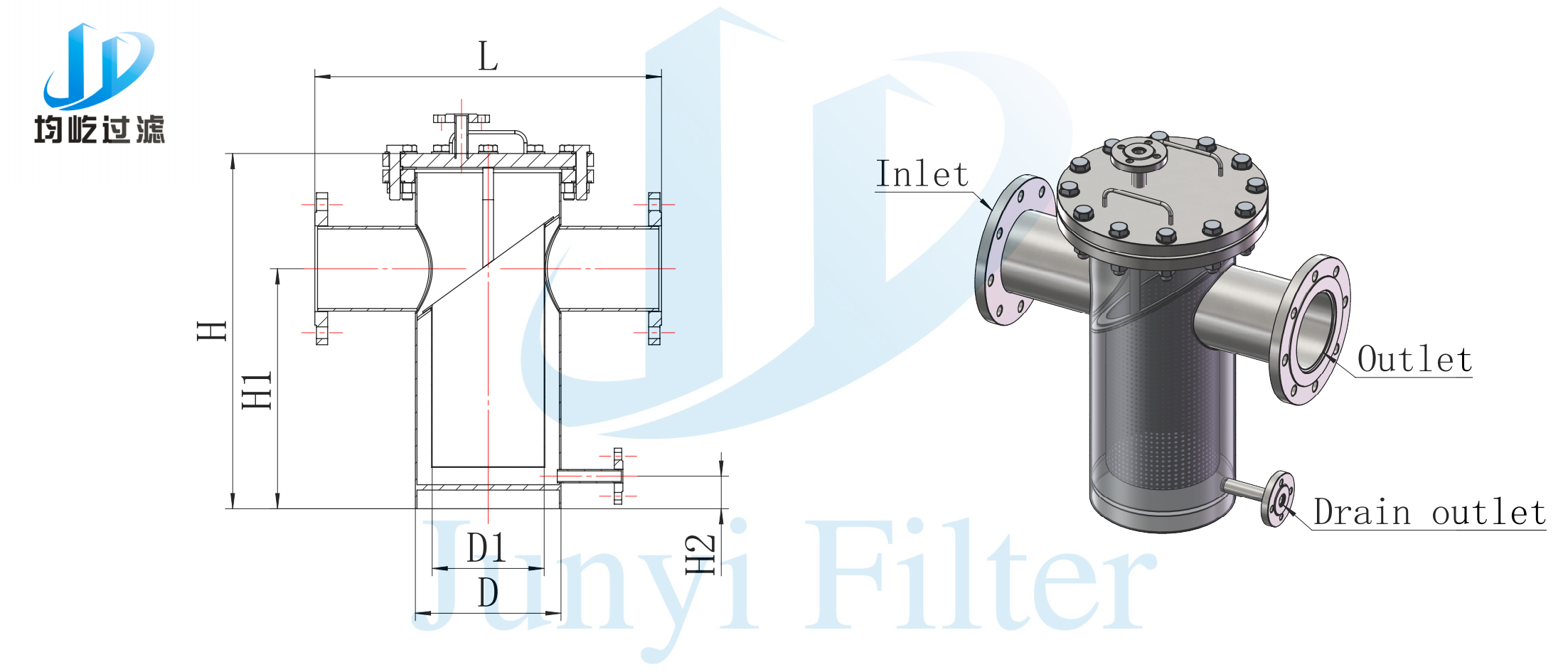

Customizable Compact Basket Strainer for Limited Space Installation

Main features and advantages:

Simple structure, durable and sturdy: Usually consists of a housing, filter basket, cover plate (top cover) and seals. Easy to manufacture and maintain, with strong pressure-bearing capacity.

Large filtration area, low pressure: Strong dirt-carrying capacity, which can extend the cleaning cycle.

Maintenance convenience: Most designs feature flange connections and quick-opening blind plates, eliminating the need to dismantle the pipeline.

Wide applicability: It can handle various media such as water, oil, and chemicals. Different filtration accuracies and materials can be selected based on the characteristics of the medium.

Key selection parameters

When choosing a suitable basket filter, the following factors need to be considered:

1. Diameter (DN) and connection method: Must match the pipe size and flange standard.

2. Design pressure (PN/Class) and temperature: Must meet the maximum pressure and temperature requirements of the process flow.

3. Filtration accuracy (mesh size or millimeters): Choose based on the requirements of the protected equipment and the size of impurities.

4. Materials: Shell/filter basket: Made of carbon steel, stainless steel, etc. Selection depends on the corrosiveness of the medium, temperature and hygiene requirements. Residue capacity: Determine the size and capacity of the filter basket based on the expected impurity content to reduce the frequency of cleaning. Special requirements: such as explosion-proof structure, insulation/heat tracing jacket, blow-off valve, differential pressure gauge, etc.

Application fields

1.Petrochemical industry: Protect pumps, compressors, flow meters, filter raw oil, chemicals, process water, etc.

2.Electric power industry: Filtration of boiler feedwater, cooling water, fuel oil and lubricating oil.

3.Food: Filtration process water, syrup, solvents, etc.

4.Water treatment and water supply: Used for coarse filtration before the water pump to remove larger particles in the water.

5.Papermaking, textile, metallurgy: Filter circulating water and chemical solutions, protecting nozzles and sensitive equipmen

6.HVAC (Heating, Ventilation, and Air Conditioning): Filters the circulating water in heating and cooling systems.

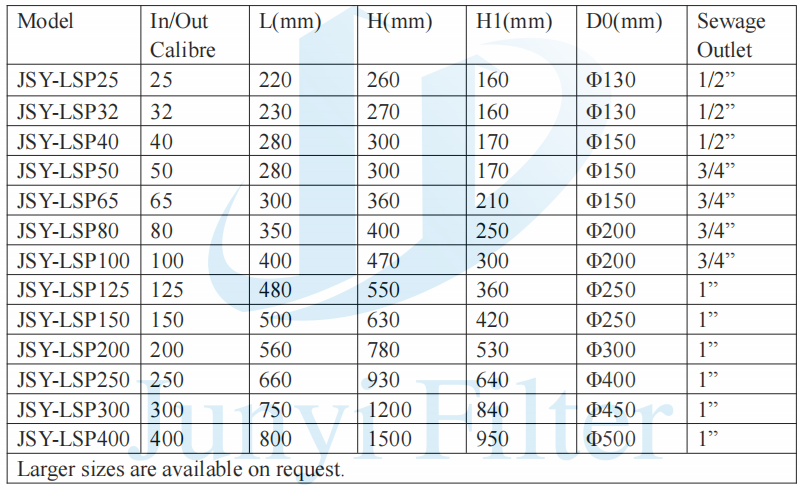

Parameter Table