Hours Continuous Filtration Municipal Sewage Treatment Vacuum Belt Press

✧ Product Features

1. Higher Filtration rates with minimum moisture content.

2. Lower operating and maintenance costs due to efficient & sturdy design.

3. Low friction advanced air box mother belt support system, Variants can be offered with slide rails or roller decks support system.

4. Controlled belt aligning systems results in maintenance free running for a long time.

5. Multi stage washing.

6. Longer life of mother belt due to less friction of air box support.

7. Drier filter cake output.

| Filter Press Model Guidance | |||||

| Liquid name | Solid-liquid ratio (%) | Specific gravity of solids | Material status | PH value | Solid particle size (mesh) |

| Temperature (℃) | Recovery of liquids/solids | Water content of filter cake | Working hours/day | Capacity/day | Whether the liquid evaporates or not |

✧ Feeding Process

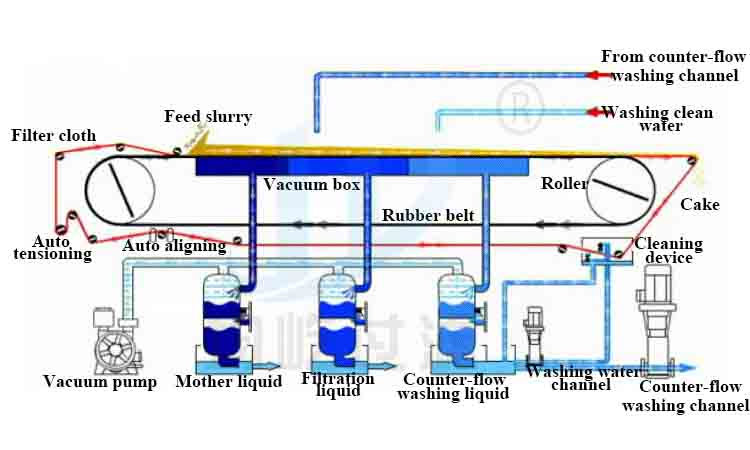

The Vacuum Belt Filter Press uses a screen cloth and rubber vacuum carrier belt in combination. As the fishtail feeder deposits slurry onto the surface of the filter cloth, the belt moves in a horizontal linear direction under the dam roller to form a cake of varying thickness. As the belt travels, negative vacuum pressure draws free filtrate out of the slurry, through the cloth, along the grooves in the carrier belt and through the center of the carrier belt into the vacuum box. This process continues until the slurry has formed a solid filter-cake, which is then discharged at the head pulley end of the belt filter.

✧ Application Industries

1. Coal, Iron ore, Lead, Copper, zinc, Nickel, etc.

2. Flue Gas Desulphurization.

3. FGD washing of gypsum cake.

4. Pyrite.

5. Magnetite.

6. Phosphate Rock.

7. Chemical Processing.

✧ Filter Press Ordering Instructions

1. Refer to the filter press selection guide, filter press overview, specifications and models, select the model and supporting equipment according to the needs.

For example: Whether the filter cake is washed or not, whether the effluent is open or close, whether the rack is corrosion-resistant or not, the mode of operation, etc., must be specified in the contract.

2. According to the special needs of customers, our company can design and produce non-standard models or customized products.

3. The product pictures provided in this document are for reference only. In case of changes, we will not give any notice and the actual order will prevail.

| Model | Treatment capacity m³/h |

Motor power KW |

leather bandwidth mm |

Slurry feed concentration (%) |

Discharge slurry concentration (%) |

Overall dimensions | ||

| Length mm |

Width mm |

Height mm |

||||||

| JY-BFP -500 |

0.5-4 | 0.75 | 500 | 3-8 | 25-40 | 4790 | 900 | 2040 |

| JY-BFP -1000 |

3-6.5 | 1.5 | 1000 | 3-8 | 25-40 | 5300 | 1500 | 2300 |

| JY-BFP -1500 |

4-9.5 | 1.5 | 1500 | 3-8 | 25-40 | 5300 | 2000 | 2300 |

| JY-BFP -2000 |

5-13 | 2.2 | 2000 | 3-8 | 25-40 | 5300 | 2500 | 2300 |

| JY-BEP -2500 |

7-15 | 4 | 2500 | 3-8 | 25-40 | 5300 | 3000 | 2300 |

| JY-BFP -3000 |

8-20 | 5.5 | 3000 | 3-8 | 25-40 | 5300 | 3500 | 2300 |

| JY-BFP -4000 |

12-30 | 7.5 | 4000 | 3-8 | 25-40 | 5800 | 4500 | 2300 |