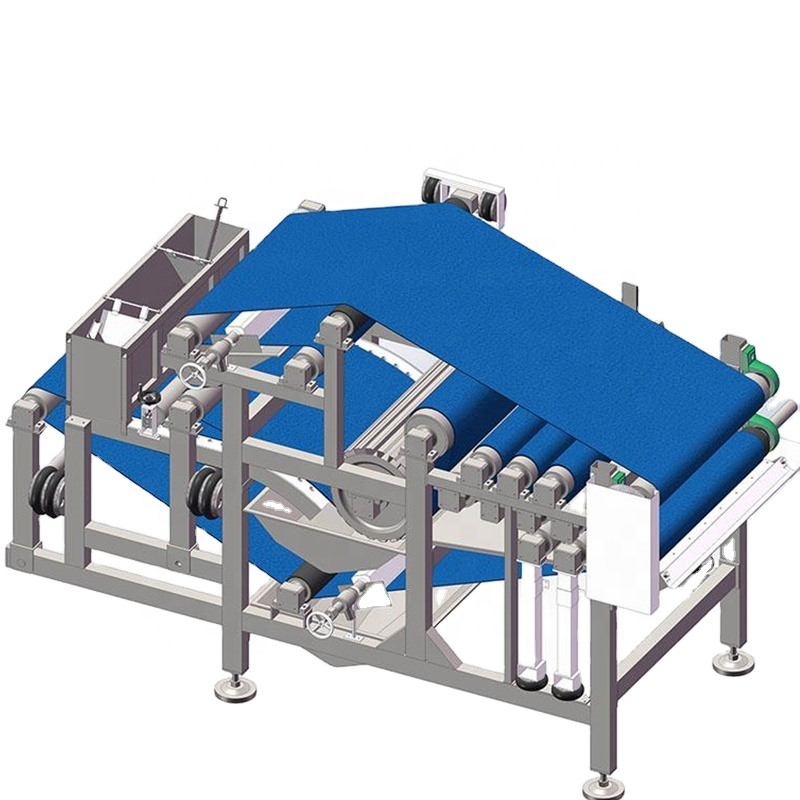

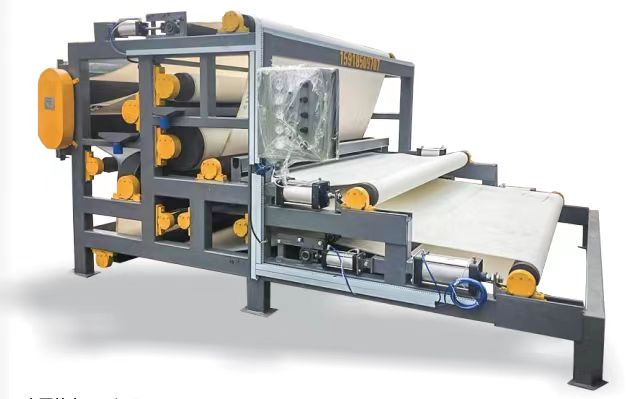

Stainless Steel Belt Filter Press For Sludge Dewatering Sand Washing Sewage Treatment Equipment

✧ Product Features

* Higher Filtration rates with minimum moisture content.

* Lower operating and maintenance costs due to efficient & sturdy design.

* Low friction advanced air box mother belt support system, Variants can be offered with slide rails or roller decks support system.

* Controlled belt aligning systems results in maintenance free running for a long time.

* Multi stage washing.

* Longer life of mother belt due to less friction of air box support.

* Drier filter cake output.

✧ Feeding Process

✧ Application Industries

It is widely used in solid-liquid separation process in petroleum, chemical, dyestuff, metallurgy, pharmacy, food, coal washing, inorganic salt, alcohol, chemical, metallurgy, pharmacy, light industry, coal, food, textile, environmental protection, energy and other industries.

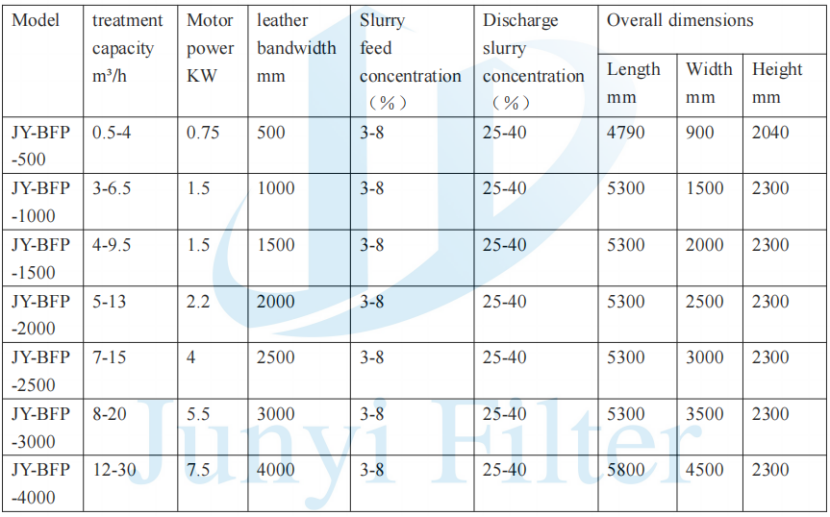

✧ Filter Press Ordering Instructions

1. Refer to the filter press selection guide, filter press overview, specifications and models, select the model and supporting equipment according to the needs.

For example: Whether the filter cake is washed or not, whether the effluent is open or close, whether the rack is corrosion-resistant or not, the mode of operation, etc., must be specified in the contract.

2. According to the special needs of customers, our company can design and produce non-standard models or customized products.

3. The product pictures provided in this document are for reference only. In case of changes, we will not give any notice and the actual order will prevail.

Main faults and troubleshooting methods

| Fault phenomenon | Fault Principle | Troubleshooting |

| Severe noise or unstable pressure in the hydraulic system | 1、The oil pump is empty or the oil suction pipe is blocked. | Oil tank refueling, solve suction pipe leakage |

| 2、The sealing surface of the filter plate is caught with misc. | Clean sealing surfaces | |

| 3、Air in the oil circuit | Exhaust air | |

| 4、Oil pump damaged or worn | Replace or repair | |

| 5、The relief valve is unstable | Replace or repair | |

| 6、Pipe vibration | Tightening or reinforcing | |

| Insufficient or no pressure in the hydraulic system | 1、Oil pump damage | Replace or repair |

|

recalibration | |

| 3、Oil viscosity is too low | Replacement of oil | |

| 4、There is a leak in the oil pump system | Repair after examination | |

| Insufficient cylinder pressure during compression | 1、Damaged or stuck high pressure relief valve | Replace or repair |

| 2、Damaged reversing valve | Replace or repair | |

| 3、Damaged large piston seal | replacement | |

| 4、Damaged small piston "0" seal | replacement | |

| 5、Damaged oil pump | Replace or repair | |

| 6、Pressure adjusted incorrectly | recalibrate | |

| Insufficient cylinder pressure when returning | 1、Damaged or stuck low pressure relief valve | Replace or repair |

| 2、Damaged small piston seal | replacement | |

| 3、Damaged small piston "0" seal | replacement | |

| Piston crawling | Air in the oil circuit | Replace or repair |

| Serious transmission noise | 1、Bearing damage | replacement |

| 2、Gear striking or wearing | Replace or repair | |

| Serious leakage between plates and frames |

|

replacement |

| 2、Debris on sealing surface | Clean | |

| 3、Filter cloth with folds, overlaps, etc. | Qualified for finishing or replacement | |

| 4、Insufficient compression force | Appropriate increase in compression force | |

| The plate and frame are broken or deformed | 1、Filter pressure too high | turn down the pressure |

| 2、High material temperature | Appropriately lowered temperatures | |

| 3、Compression force too high | Adjust the compression force appropriately | |

| 4、Filtering too fast | Reduced filtration rate | |

| 5、Clogged feed hole | Cleaning the feed hole | |

| 6、Stopping in the middle of filtration | Do not stop in the middle of filtration | |

| The replenishment system works frequently | 1、The hydraulic control check valve is not tightly closed | replacement |

| 2、Leakage in the cylinder | Replacement of cylinder seals | |

| Hydraulic reversing valve failure | Spool stuck or damaged | Disassemble and clean or replace the directional valve |

| The trolley can't be pulled back because of the back and forth impact. | 1、Low oil motor oil circuit pressure | adjust |

| 2、The pressure relay pressure is low | adjust | |

| Failure to follow procedures | Failure of a component of the hydraulic system, electrical system | Repair or replace symptomatically after inspection |

| Diaphragm damage | 1、insufficient air pressure | Reduced press pressure |

| 2、Insufficient feed | Pressing after filling the chamber with material | |

| 3、A foreign object has punctured the diaphragm. | foreign matter removal | |

| Bending damage to main beam | 1、Poor or uneven foundations | Refurbish or redo |