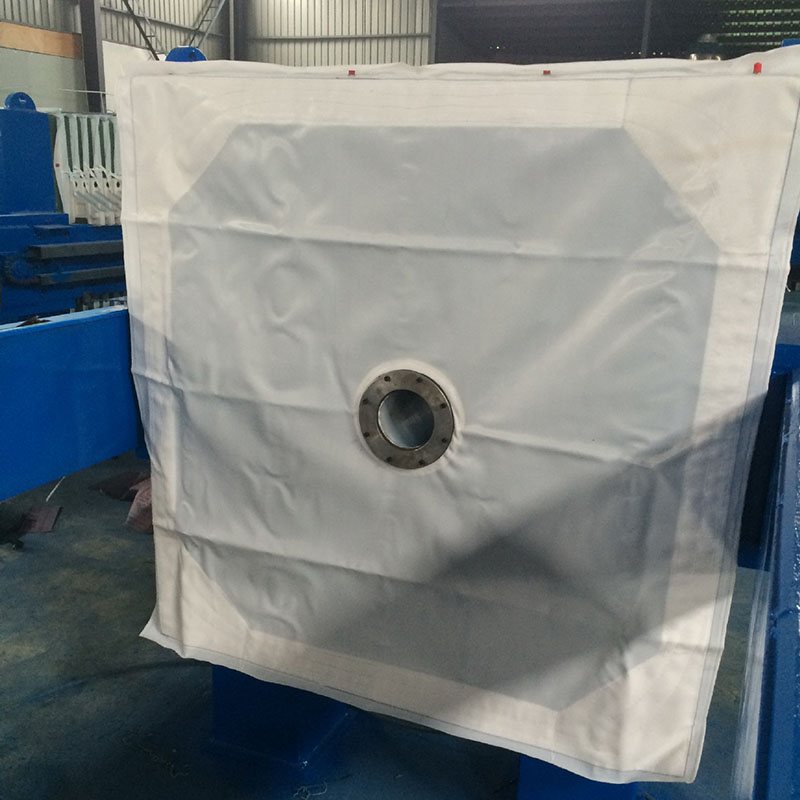

Mono-filament Filter Cloth for Filter Press

Advantages

Sigle synthetic fiber woven, strong, not easy to block, there will be no yarn breakage. The surface is heat-setting treatment, high stability, not easy to deform, and uniform pore size. Mono-filament filter cloth with calendared surface, smooth surface, easy to peel off the filter cake, easy to clean and regenerate the filter cloth.

Performance

High filtration efficiency, easy to clean, high strength, service life is 10 times of general fabrics, the highest filtration precision can reach 0.005μm.

Product coefficients

Breaking strength, breaking elongation, thickness, air permeability, abrasion resistance and top breaking force.

Uses

Rubber, ceramics, pharmaceuticals, food, metallurgy and so on.

Application

Petroleum, chemical, pharmaceutical, sugar, food, coal washing, grease, printing and dyeing, brewing, ceramics, mining metallurgy, sewage treatment and other fields.

✧ Parameter List

| Model | Warp and Weft Density | rupture strength N15×20CM | Elongation rate % | Thicknesses (mm) | Weightg/㎡ | permeability10-3M3/M2.s | |||

| Lon | Lat | Lon | Lat | Lon | Lat | ||||

| 407 | 240 | 187 | 2915 | 1537 | 59.2 | 46.2 | 0.42 | 195 | 30 |

| 601 | 132 | 114 | 3410 | 3360 | 39 | 32 | 0.49 | 222 | 220 |

| 663 | 192 | 140 | 2388 | 2200 | 39.6 | 34.2 | 0.58 | 264 | 28 |