New products in 2025 High Pressure Reaction Kettle with Heating and Cooling System

Core Advantage

✅ Robust and durable structure

Diverse materials: stainless steel (304/316L), enamel glass, hastelloy, etc., resistant to acids and alkalis, corrosion-resistant.

Sealing system: Mechanical seal / magnetic seal are available options. It has no leakage and is suitable for volatile or hazardous media.

✅ Precise process control

Heating/Cooling: Jacketed design (steam, oil bath or water circulation), temperature is uniformly controllable.

Mixing system: Adjustable-speed stirring (anchor type/propeller type/turbine type), resulting in more uniform mixing.

✅ Safe and reliable

Explosion-proof motor: Compliant with ATEX standards, suitable for environments prone to flammability and explosion.

Pressure/Vacuum: Equipped with safety valve and pressure gauge, capable of supporting positive or negative pressure reactions.

✅ Highly customizable

Capacity flexibility: Customizable from 5L (for laboratories) to 10,000L (for industrial use).

Expansion features: Condenser can be installed, CIP cleaning system and PLC automatic control can also be added.

Application Fields

Chemical Industry: Polymerization reactions, dye synthesis, catalyst preparation, etc.

Pharmaceutical industry: Drug synthesis, solvent recovery, vacuum concentration, etc.

Food processing: Heating and mixing of jams, seasonings and edible oils.

Coatings/Glues: Resin polymerization, viscosity adjustment, etc. processes.

Why choose us?

Over 10 years of industry experience, providing OEM/ODM services, and certified to CE, ISO, and ASME standards.

24-hour technical support, 1-year warranty, lifetime maintenance.

Fast delivery: Customized solutions will be completed within 30 days.

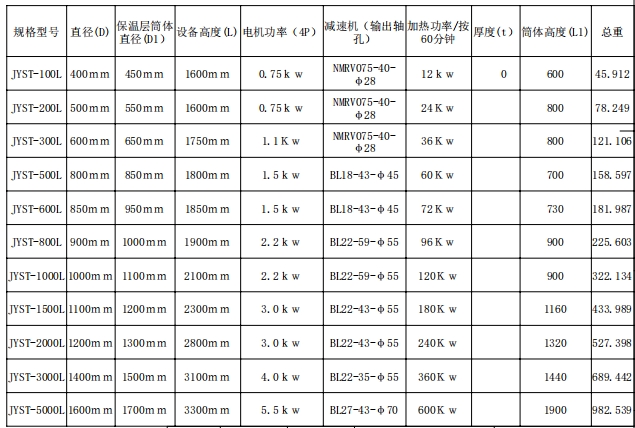

Parameters