Small high-quality sludge belt dewatering machine

>>Sewage treatment equipment suitable for use in a residential area, villages, towns and villages, office buildings, hotels, restaurants, nursing homes, authority, force, highways, railways, factories, mines, scenic spots such as sewage and similar slaughter, aquatic products processing, food and other small and medium size industrial organic wastewater treatment and reuse. >>The sewage treated by the equipment can meet the national discharge standard. The design of sewage treatment mainly is the treatment of sewage and similar industrial organic sewage, its main treatment means is to use at present relatively mature biochemical treatment technology contact oxidation method, water quality design parameter also presses general sewage water quality design calculation.

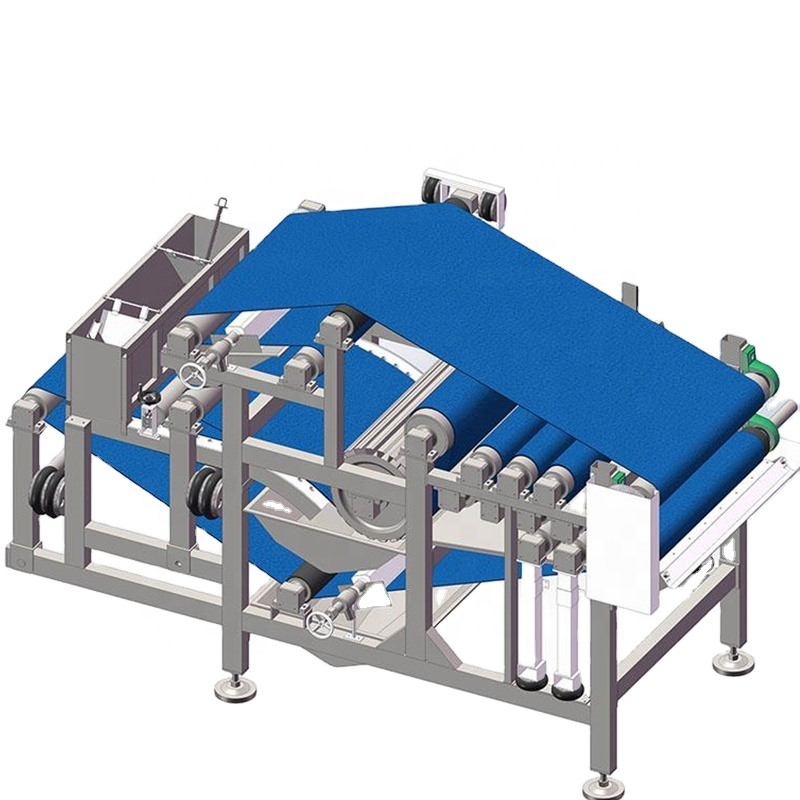

1. Material of the main structure : SUS304/316

2. Belt : Has a long service life

3. Low power consumption, slow-speed of revolution and low noise

4. Adjustment of belt: Pneumatic regulated, ensures the stability of the machine

5. Multi-point safety detection and emergency stop device:improve the operation.

6. The design of the system is obviously humanized and provides convenience in operation and maintenance.

printing and dyeing sludge, electroplating sludge,

papermaking sludge, chemical sludge, municipal sewage sludge,

mining sludge, heavy metal sludge, leather sludge,

drilling sludge, brewing sludge, food sludge.