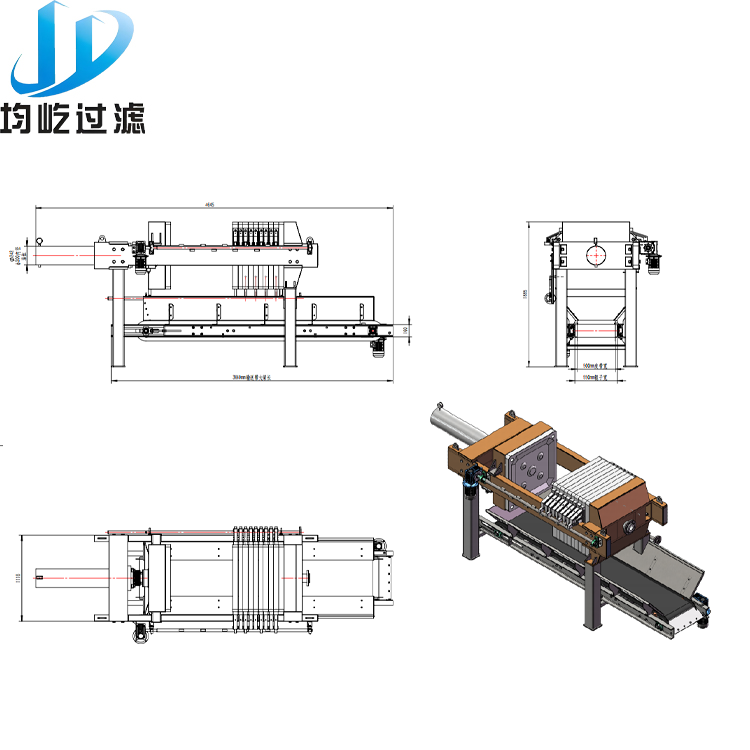

870mm Chamber Filter Press with Vibrating Discharge & Stainless Water Tank

Core Advantages

✅ Efficient Dehydration By adopting the diaphragm secondary pressing technology, the filtration cake degree is below 60%, which is 30% higher than that of the ordinary filter press in terms of dehydration rate. Processing capacity: 50 – 80 tons per hour (adjustable according to material characteristics)

✅ Intelligent and saves manpower One-click operation: PLC controls the hydraulic opening of the filter, vibration for discharging, and conveyor belt transportation. No need for manual tapping of the filter cloth.

✅ Durable and energy-efficient The filter plate is made of reinforced polypropylene, which is resistant to acids and alkalis, resistant to deformation, and has a long service life. Energy-saving design: Compared to traditional models, it saves 20% of electricity.

✅ Complete set design Standard equipment: Stainless steel chain plate conveyor (length can be customized) + Corrosion-resistant PVC water collection tank Support the installation of a high-pressure water flushing system to prevent the filter cloth from getting clogged.

Work Flow

1.Feed Stage: Sludge is pumped into the filter chamber for initial filtration

2.Diaphragm compression: High-pressure water is used to squeeze the filter cake, achieving further dehydration.

3.Automatic discharging: Hydraulic automatic opening of filter plates + Vibration discharging

4.Discharge and collection: The filter cake is transported out by the conveyor, and the filtrate flows into the collection tank.

Applicable Industries and Materials

Mining: Tailings from gold mines/copper mines, sand washing slurry

Environmental Protection: Municipal sludge, river sediment

Chemicals: Pigments, titanium dioxide, calcium carbonate

Food: Distiller’s grains, bean meal, starch slurry

How to choose the right model?

- What is the liquid that needs filtering?

2. What is the flow rate?

3. Temperature/PH value?

4. What are the main solid impurities that need to be filtered from the liquid? What is their content?

We can make recommendations based on this information.