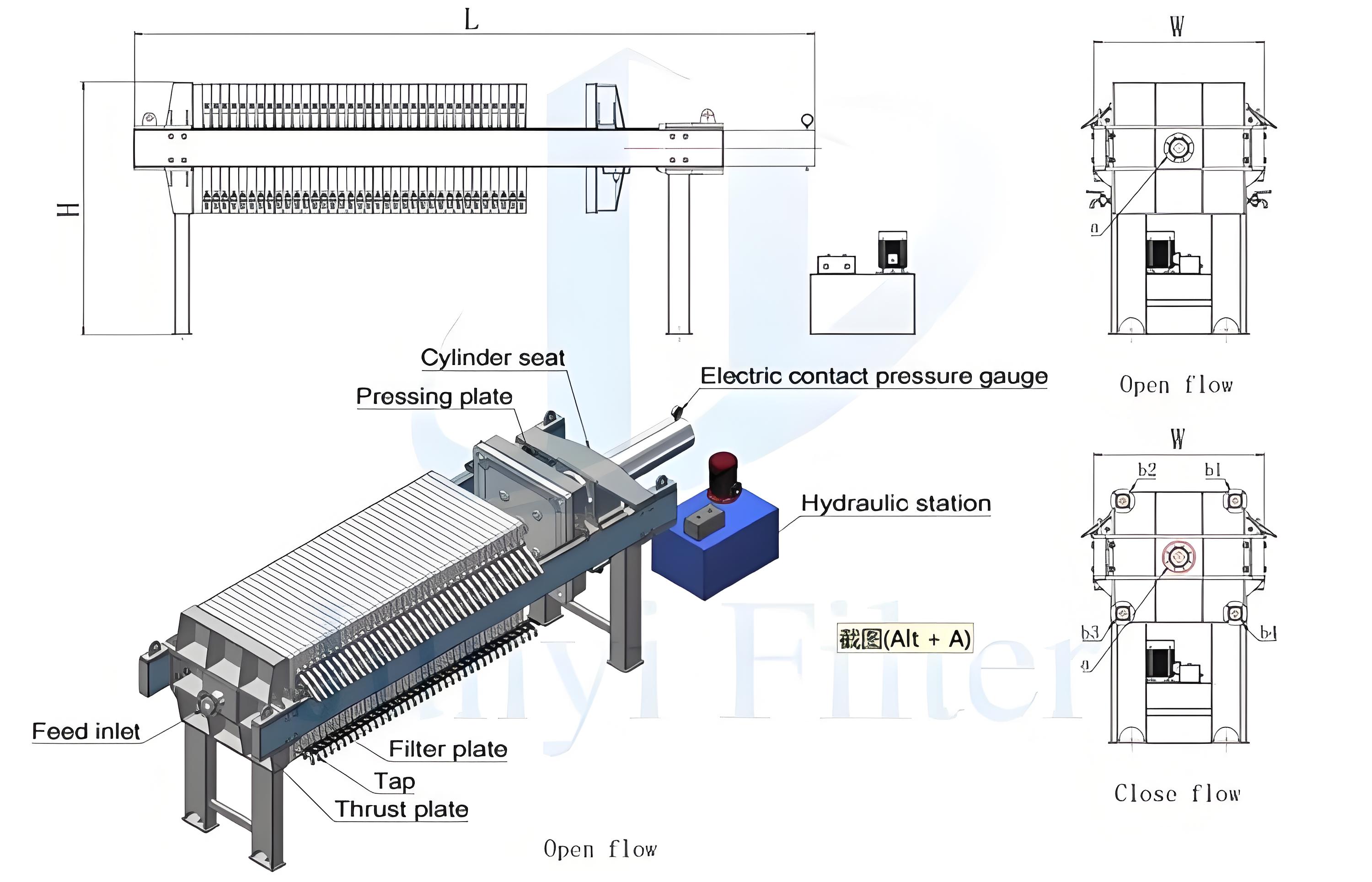

630 Sealed Automatic Pressurization Filter Machine – Hydraulic Drive – High-Pressure Filtration System

Main structural components

Frame part: High-strength steel structure, supporting the filter plates and the hydraulic system.

Filter plate and filter cloth: The material of the filter plate can be polypropylene (PP), rubber, stainless steel, etc.; the filter cloth is selected according to the characteristics of the material.

Hydraulic system: Provides high-pressure power (with a pressure range typically between 0.5 and 2.0 MPa), ensuring the compression of the filter plates and maintaining the pressure.

Automatic plate-lowering system (optional): Enables the automatic discharge of filter plates, enhancing efficiency.

Electrical control cabinet: Controlled by PLC or touch screen, achieving automated operation.

Working Principle

Feed stage: The materials are pumped into the filter chamber. Under pressure, the solids are retained by the filter cloth to form a filter cake, while the liquid passes through the filter cloth and is discharged.

Pressing stage (optional): Hydraulic or pneumatic pressure is applied to further squeeze the filter cake, reducing the moisture content.

Discharge stage: The filter plates are released, and the filter cake automatically or manually falls off. Some models are equipped with vibration or scraper assistance for discharge.

Product Features

Sealed and Environmentally Friendly: The sealed filter plate design prevents the contact between the material and air, making it suitable for flammable, toxic or highly pure materials.

Efficient dehydration: The high-pressure hydraulic system significantly reduces the moisture content of the filter cake (down to 30% or less).

High degree of automation: Supports functions such as automatic clamping, pulling, and cleaning, reducing the need for manual intervention.

High corrosion resistance: The filter plates and pipeline materials can be selected with anti-corrosion options according to the medium.

Energy-saving and low-consumption: The hydraulic system precisely controls the pressure, resulting in lower energy consumption compared to traditional mechanical filter presses.

Application Fields

Chemical Industry: Pigments, dyes, catalyst recovery.

Environmental protection: Sludge dewatering, wastewater treatment.

Mining: Dry discharge of tailings, dehydration of concentrate.

Food: Juice clarification, fermentation cell separation.

Selection Suggestions

The filter plate material, filtration area, and automation configuration should be selected based on the material characteristics (particle size, viscosity, corrosiveness), processing volume, and moisture content requirements.