Automatic belt filter press for sludge dewatering in mineral processing industry

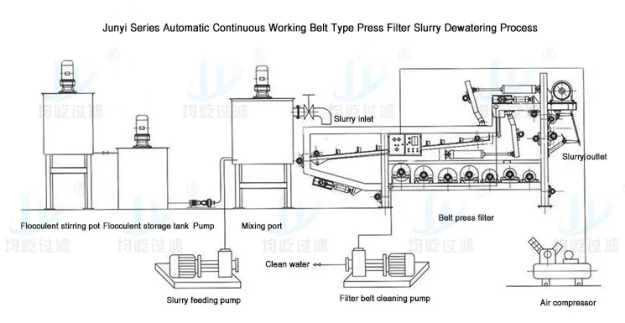

working principle:

Belt filter press is a continuous solid-liquid separation equipment. Its working process is to feed the materials that need to be processed (usually sludge or other suspensions containing solid particles) into the feed inlet of the equipment. The material will first enter the gravity dehydration zone, where a large amount of free water will be separated from the material due to the effect of gravity and flow away through the gaps in the filter belt. Then, the material will enter the wedge-shaped pressing zone, where the space gradually shrinks and an increasing pressure is applied to the material to further squeeze out the moisture. Finally, the material enters the pressing zone, where the remaining water is squeezed out by the pressing rollers to form a filter cake, while the separated water is discharged from below the filter belt.

Main structural components:

Filter belt: It is the core component of a belt filter press, usually made of materials such as polyester fibers, with certain strength and good filtration performance. The filter belt continuously circulates throughout the entire working process, carrying animal materials through various working areas. The filter belt needs to have good wear resistance and corrosion resistance to ensure long-term stable operation.

Drive device: Provides power for the operation of the filter belt, ensuring stable operation at an appropriate speed. It generally includes components such as motors, reducers, and drive rollers. The reducer is driven by the motor, and then the roller is driven by the reducer to rotate, thereby driving the movement of the filter belt.

Squeezing roller system: composed of multiple squeezing rollers, which squeeze materials in the squeezing area. The arrangement and pressure settings of these press rollers vary depending on the material and processing requirements. Common combinations of press rollers with different diameters and hardness are used to achieve different pressing effects.

Tensioning device: Maintain the tension state of the filter belt to prevent it from loosening during operation. The tensioning device generally achieves the tensioning of the filter belt by adjusting the position or tension of the tensioning roller, ensuring close contact between the filter belt and various working components, thereby ensuring the filtering and pressing effect.

Cleaning device: used to clean the filter belt to prevent residual materials on the filter belt from blocking the filter holes and affecting the filtration effect. The cleaning device will rinse the filter belt during operation, and the cleaning solution used is usually water or chemical cleaning agents. The cleaned wastewater will be collected and discharged.

Application areas:

Sewage treatment industry: Belt filter presses are widely used for sludge dewatering treatment in urban sewage treatment plants and industrial wastewater treatment plants. After treatment, the moisture content of the sludge will be significantly reduced, forming a filter cake that is easy to transport and dispose of. It can be used for further treatment such as landfilling, incineration, or as fertilizer.

Food processing industry: For wastewater containing solid impurities generated during food processing, such as fruit residue in fruit processing and starch residue wastewater in starch production, belt filter presses can separate the solid and liquid parts, allowing the solid part to be used as a by-product, while the separated water can be further treated or discharged.

Chemical industry: The treatment of solid and liquid containing waste generated during chemical production processes, such as precipitated chemical waste and suspensions from chemical synthesis processes, can be achieved through solid-liquid separation using a belt filter press, reducing the volume and weight of waste, lowering treatment costs and environmental pollution risks.

advantage:

Continuous operation: capable of processing materials continuously, with a large processing capacity, suitable for

Write your message here and send it to us