SS304 SS316l Multi Bag Filter for Textile Printing Dyeing Industry

✧ Product Features

A.High filtration efficiency: Multi-bag filter can use multiple filter bags at the same time, effectively increasing the filtration area and improving the filtration efficiency.

B. Large processing capacity: Multi-bag filter consists of multiple filter bags, which can process a large number of fluids at the same time.

C. Flexible and adjustable: Multi-bag filters usually have an adjustable design, which allows you to choose to use different numbers of filter bags according to actual needs.

D. Easy maintenance: The filter bags of multi-bag filters can be replaced or cleaned to maintain the performance and life of the filter.

E. Customization: Multi-bag filters can be designed and customized according to specific application requirements. Filter bags of different materials, different pore sizes and filtration levels can be selected to suit different fluids and contaminants.

✧ Application Industries

Industrial manufacturing: Bag filters are commonly used for particulate filtration in industrial production, such as metal processing, chemical, pharmaceutical, plastics and other industries.

Food and beverage: bag filter can be used for liquid filtration in food and beverage processing, such as fruit juice, beer, dairy products and so on.

Wastewater treatment: Bag filters are used in wastewater treatment plants to remove suspended particles and solid particles and improve water quality.

Oil and gas: bag filters are used for filtration and separation in oil and gas extraction, refining and gas processing.

Automotive industry: Bag filters are used for spraying, baking and airflow purification in the automotive manufacturing process.

Wood processing: bag filters are used for filtration of dust and particles in wood processing to improve air quality.

Coal mining and ore processing: bag filters are used for dust control and environmental protection in coal mining and ore processing.

✧ Filter Press Ordering Instructions

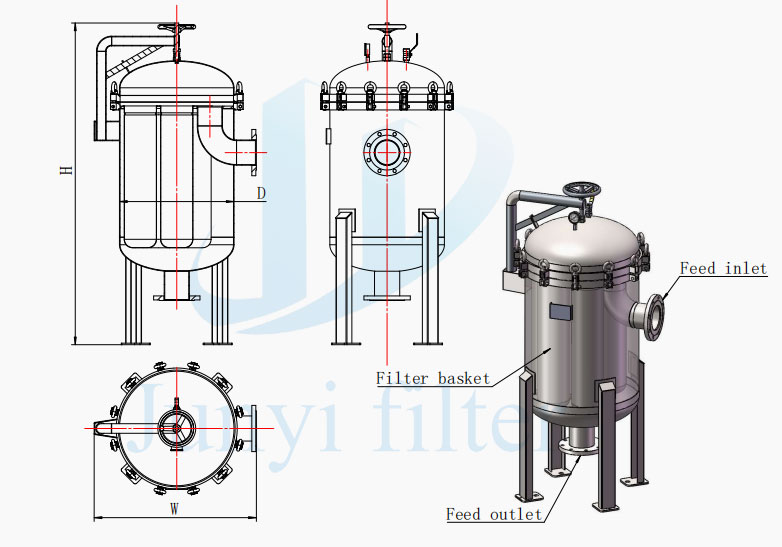

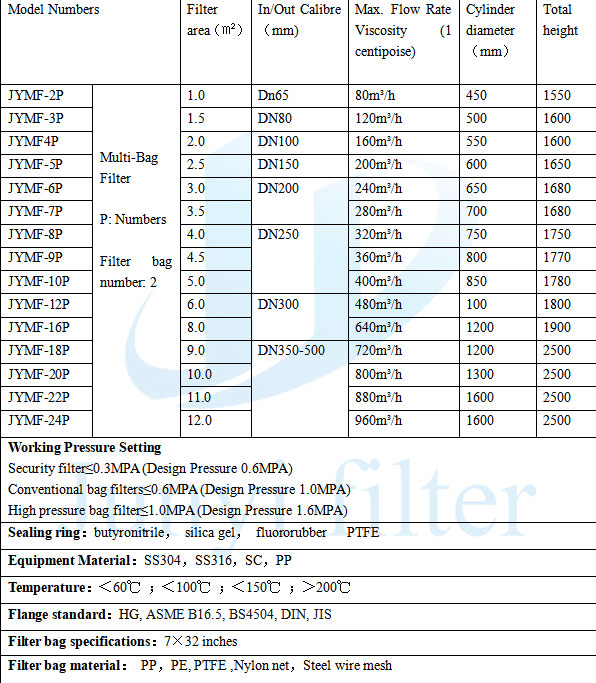

1. Refer to the bag filter selection guide, bag filter overview, specifications and models, and select the model and supporting equipment according to the requirements.

2. According to the special needs of customers, our company can design and produce non-standard models or customized products.

3. The product pictures and parameters provided in this material are for reference only, subject to change without notice and actual ordering.